The Oxford LPP™ – Innovative Design - Cutting Energy Costs by up to 50%

Steve Bohner is a long-time resident and businessman from Oxford County. His accolades are impressive and include, Founder and President of Hydra Dyne Tech, President of Invaware Corporation, and the owner of The Oxford Hills -an 18-hole golf course with high quality amenities and destination spot. What does an engineering company, a software company, and a golf course have in common? The parallels between these companies are a commitment to seeking dynamic approaches to developing methods and systems to increase efficiency. And that’s no joke. In recognizing needs for development and refinement, Steve has extensive experience in taking the initiative to create cuttingedge, high-quality equipment and services for all his customers.

Under Steve’s direction, The Oxford Hills has undergone renovations to rejuvenate an overgrown course to become a class-one, scenic golfing experience. Steve has an extensive background in utilizing new technologies and equipment to meet needs in the most efficient ways. During revitalization to optimize the quality of the course, a sustainable approach was taken to ensure that environmental aspects were considered in conjunction with being profitable. As an example, in harmony with conserving the natural environment, tiles were installed to help collect water runoff during the spring and from surrounding areas to create a pond feature.

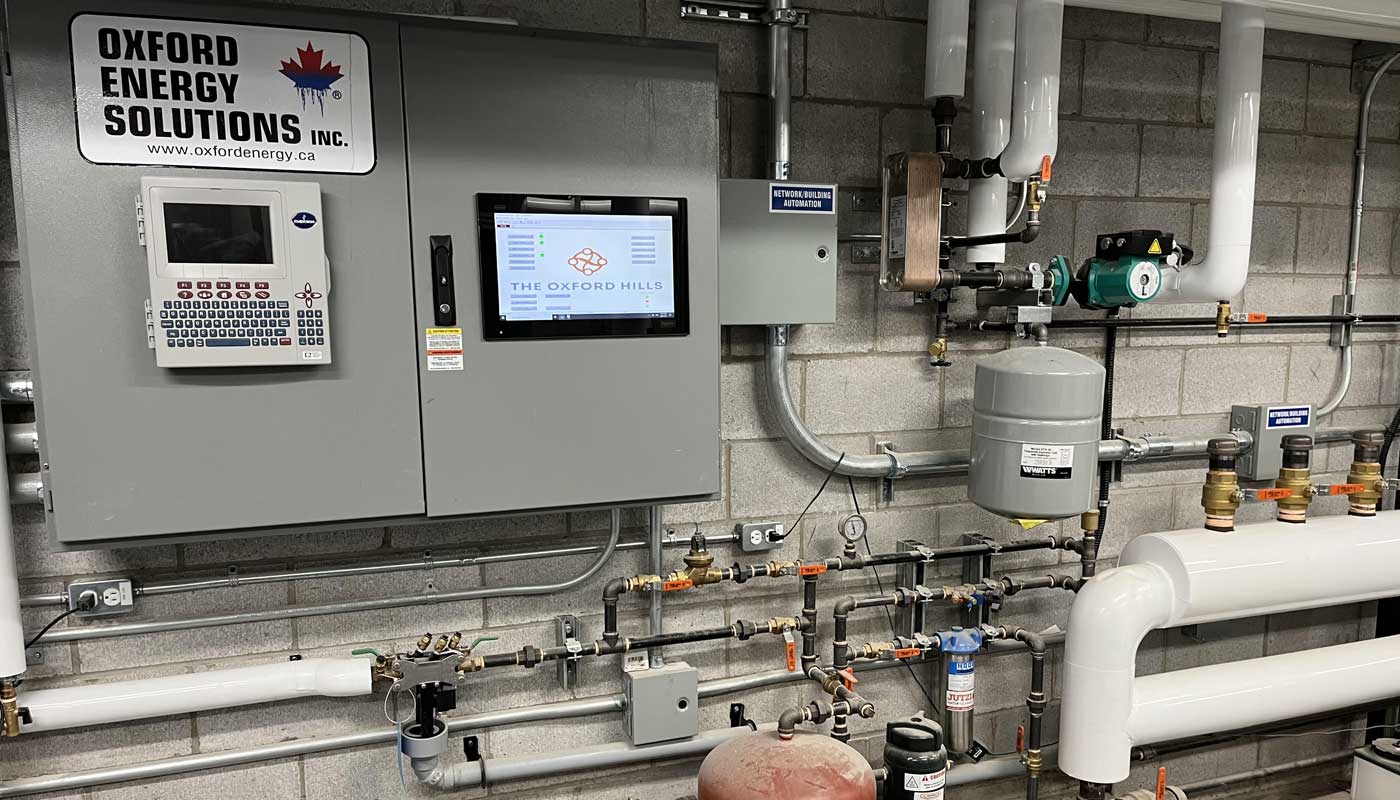

In partnership with OES, the Oxford Hills is implementing new technology and equipment that will be integrated to provide a cohesive energy-efficient refrigeration system. All refrigeration and a/c at the facility will utilize the water required for the large irrigation system as the condensing medium. There is no waste of water. This allows for lower compression ratios as well as the elimination of outdoor condensers around the club house, which is beneficial from both a visual and noise aspect. All the refrigeration, (3 walk in coolers and 1 walk in freezer), are driven from a single water-cooled Oxford LPP system. The OLPP uses low GWP HFO R-513a refrigerant, Sensori control and variable speed scroll compressors.

A/C Chillers are driven with Oxford Gas Compression’s VAPOUR DRIVE P-22 OIL FREE compressor- a water cooled, VFD controlled compressor that can vary from 0-100% speed without limitation. It uses low GWP/HFO R-515B refrigerant and is the first 100% oil free, semi-hermetic, magnetically coupled scroll compressor with full speed variation running on the lowest GWP/HFO on the market today. The Sensori control platform has secure-connect remote access and integration that not only provides the refrigeration and mechanical backbone of the system but also gives insight into other control systems utilized at the facility such as the irrigation control.

By integrating the cutting-edge design of the Oxford Low Pressure Platform, The Oxford Hills is using a low-pressure refrigerant with a low Global Warming Potential (GWP), cutting energy costs by up to 50% and implementing technologies that will save on maintenance costs. All equipment has been integrated into a rural single phase power source and eliminates any inrush current. Renovations at The Oxford Hills include incorporating top quality equipment and adopting environmentally conscious practices while increasing profitability. Steve and his team are setting the course for a sustainable path towards a bright future.