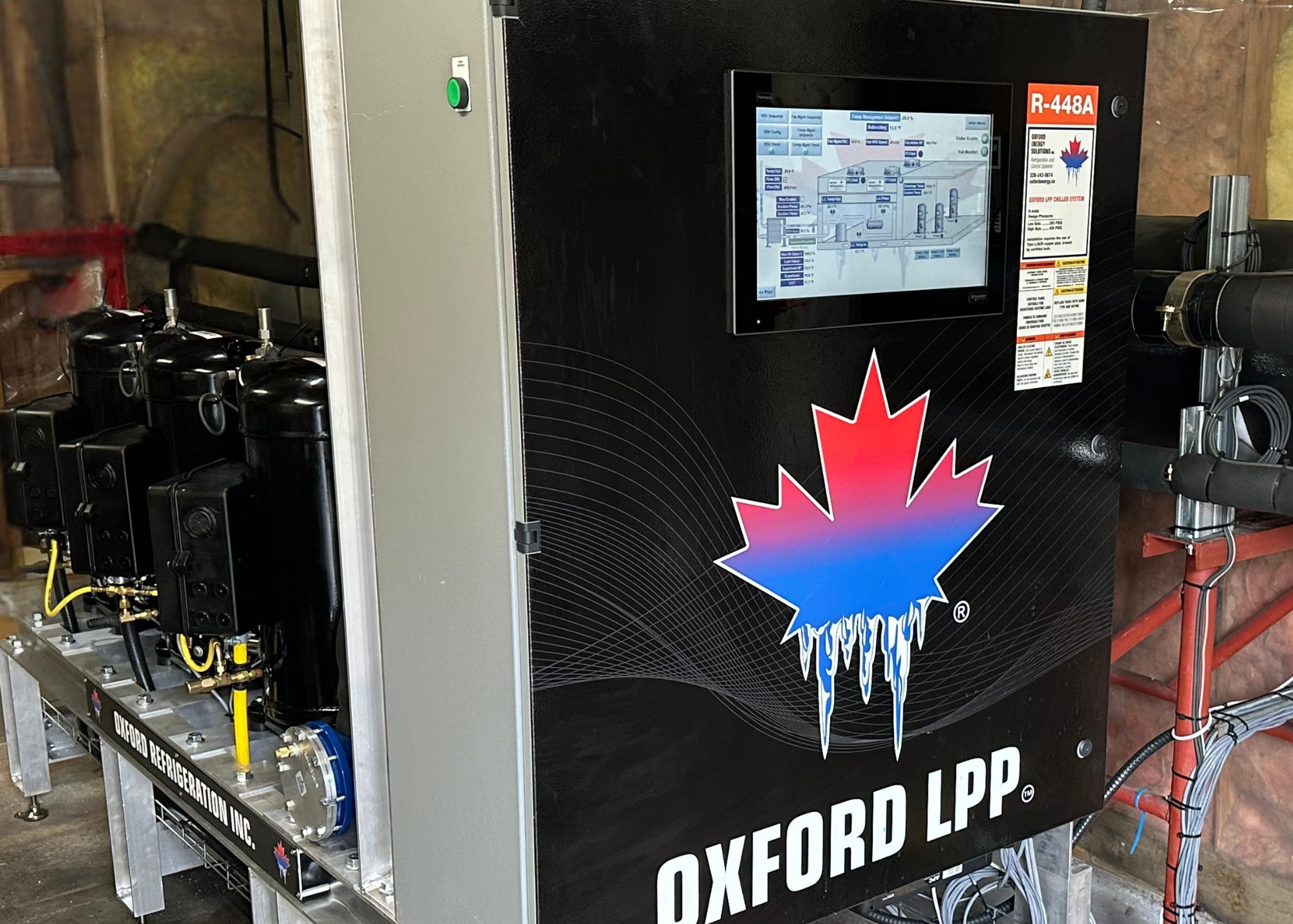

Introducing the revolutionary

Sensori Control ™ platform

A pioneering breakthrough in the refrigeration industry. This innovative system is designed with an open structure, ensuring limitless possibilities for future designs and adaptable equipment.

Seamless Integration and Customization:

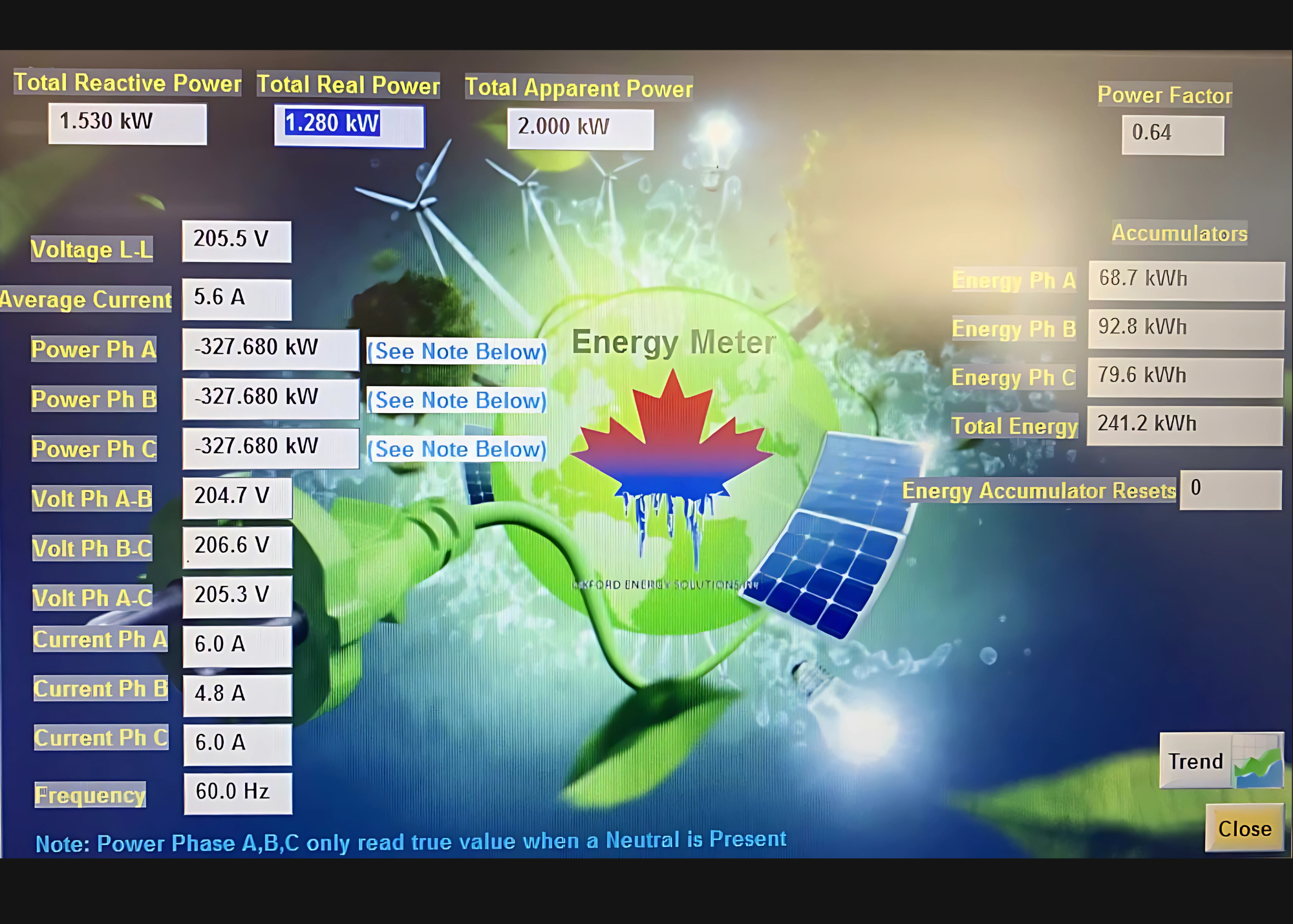

At Oxford Energy Solutions, we are committed to reducing food waste without compromising the performance of the refrigeration system. In a rapidly changing world, we recognize the need for a platform that seamlessly integrates with existing store architectures, including refrigeration, lighting, HVAC, retail, heating, alarms, and customer monitoring systems, rather than creating yet another isolated independent system.

With Sensori Control™, we remove limitations, empowering end-users to customize the system according to their preferences. Users can effortlessly add their own programming, seamlessly integrate with existing and new architectures, and enjoy the freedom to expand the system as they desire.

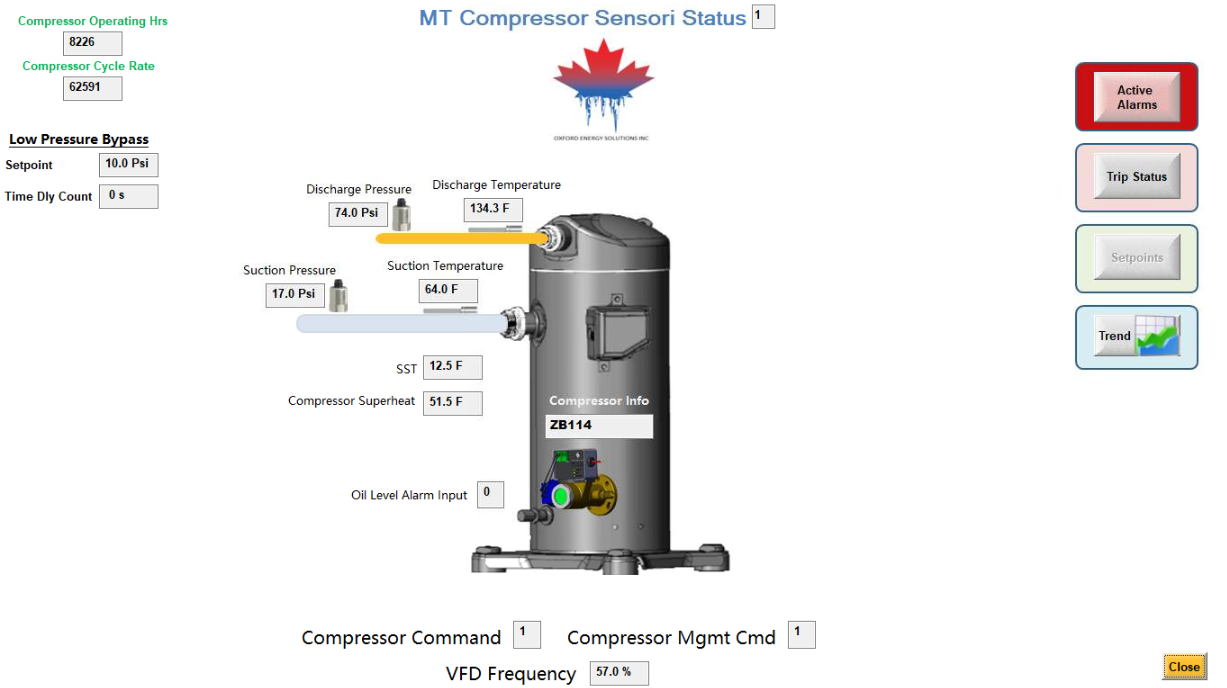

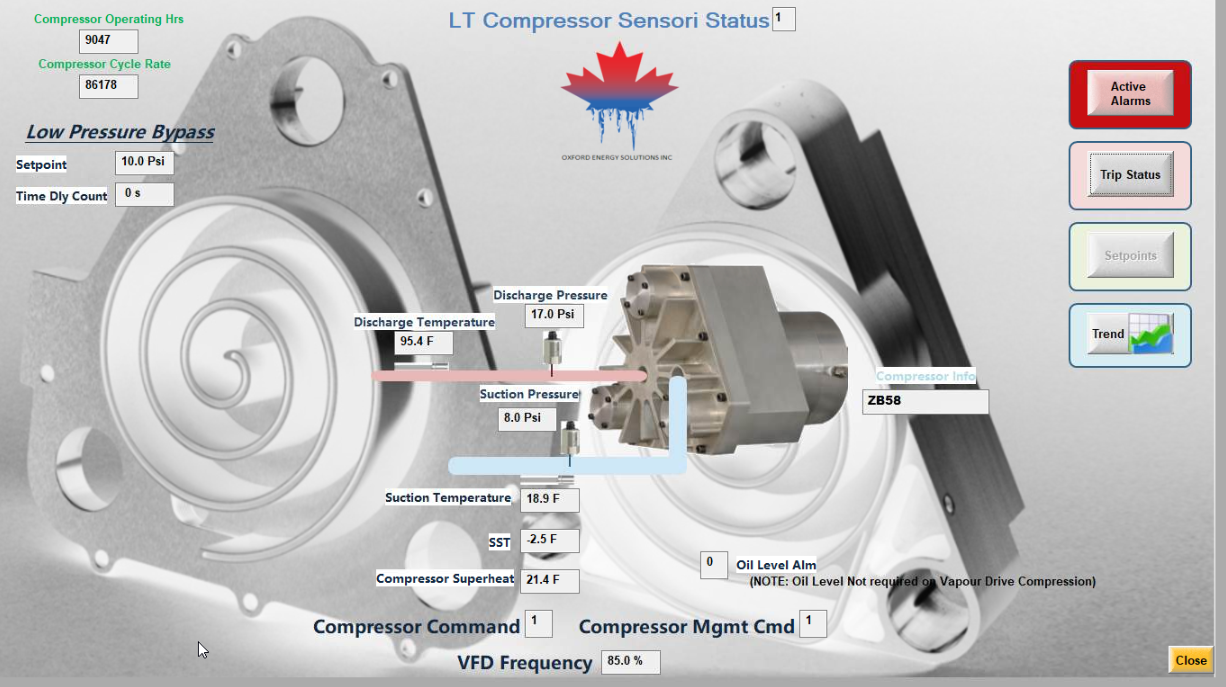

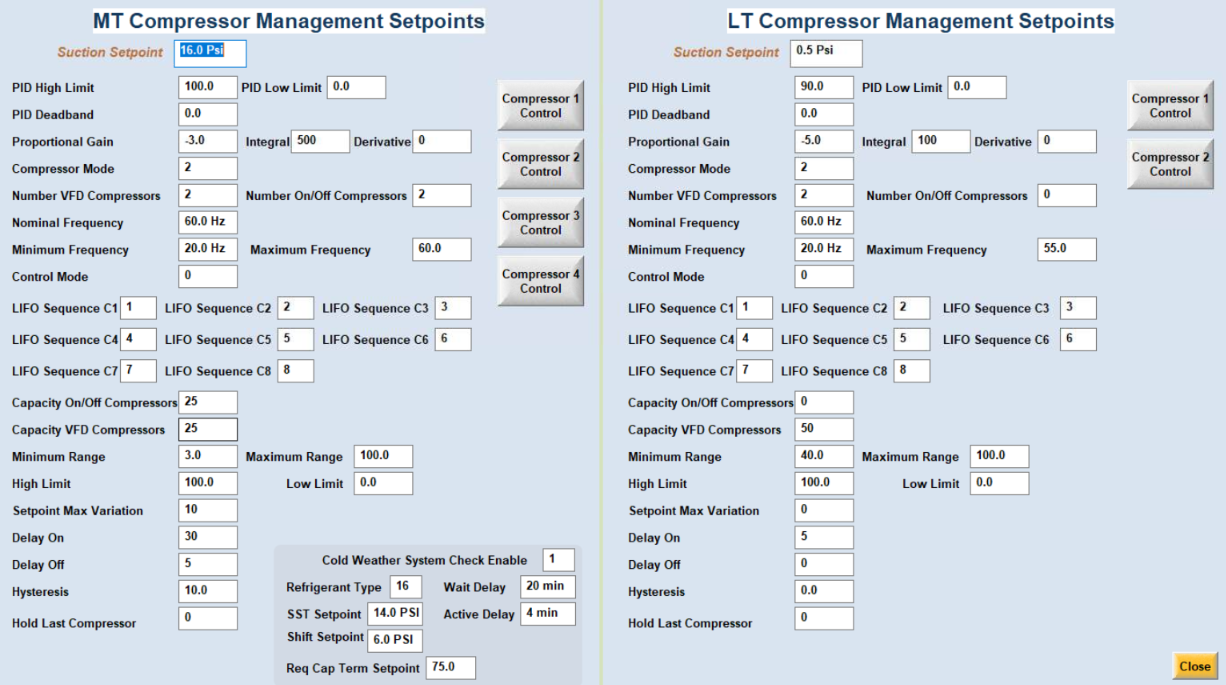

Adaptive Compressor Management:

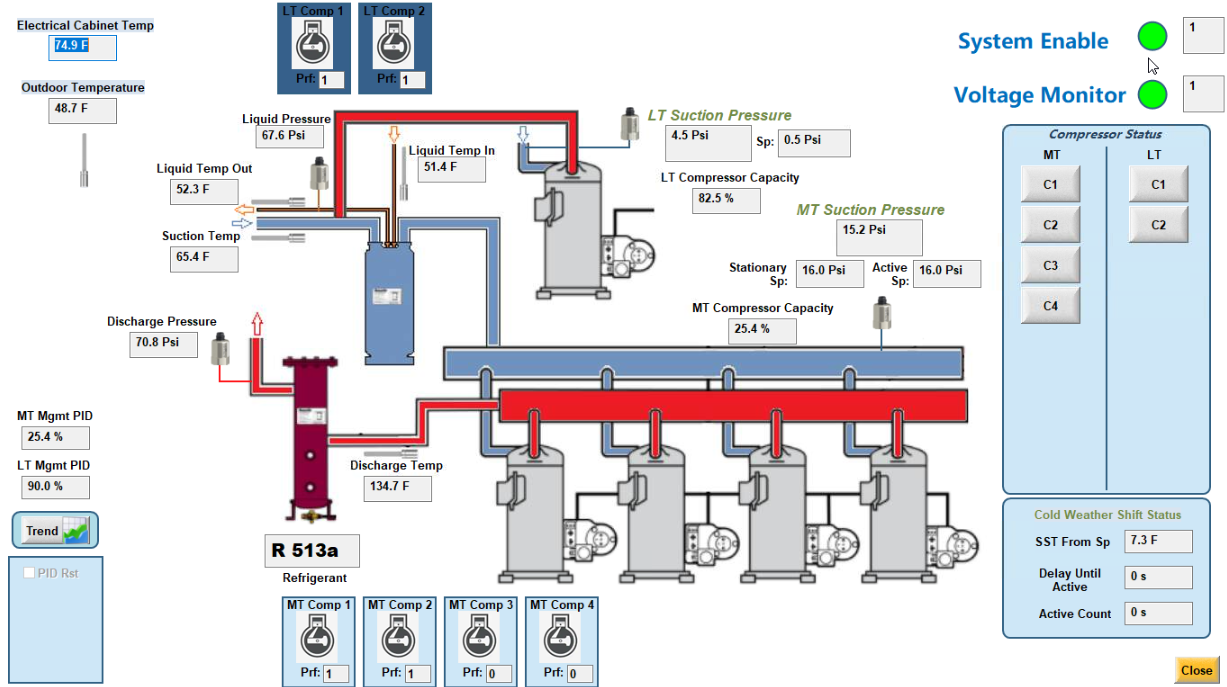

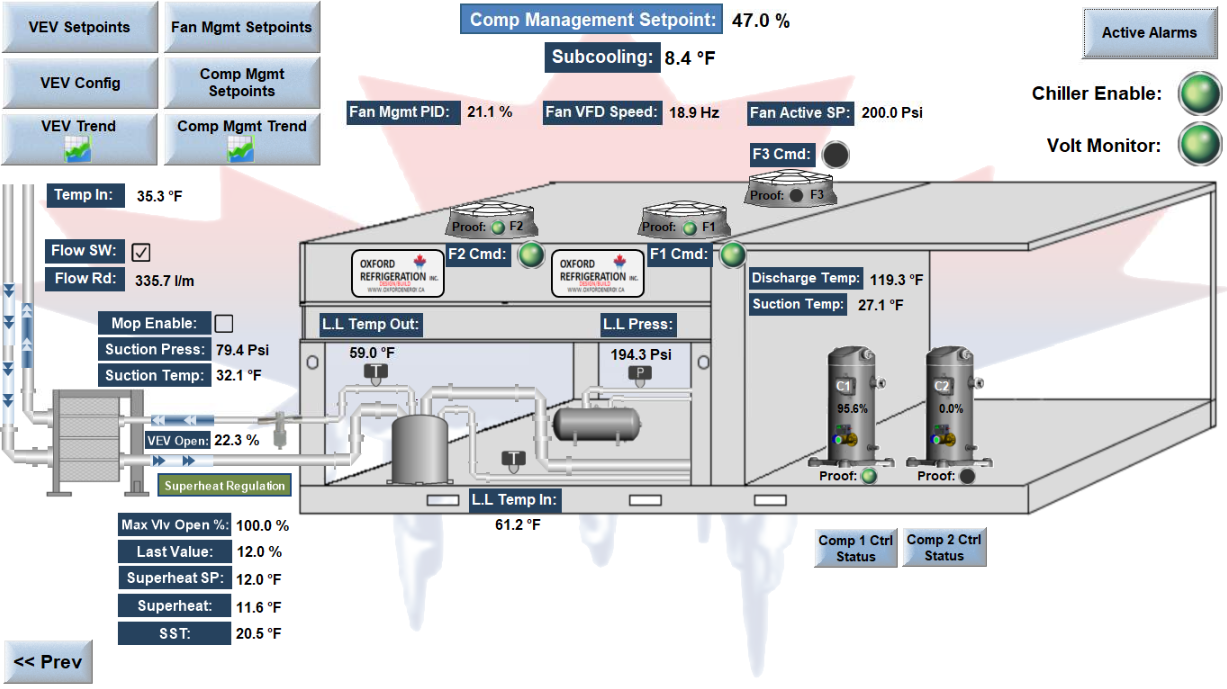

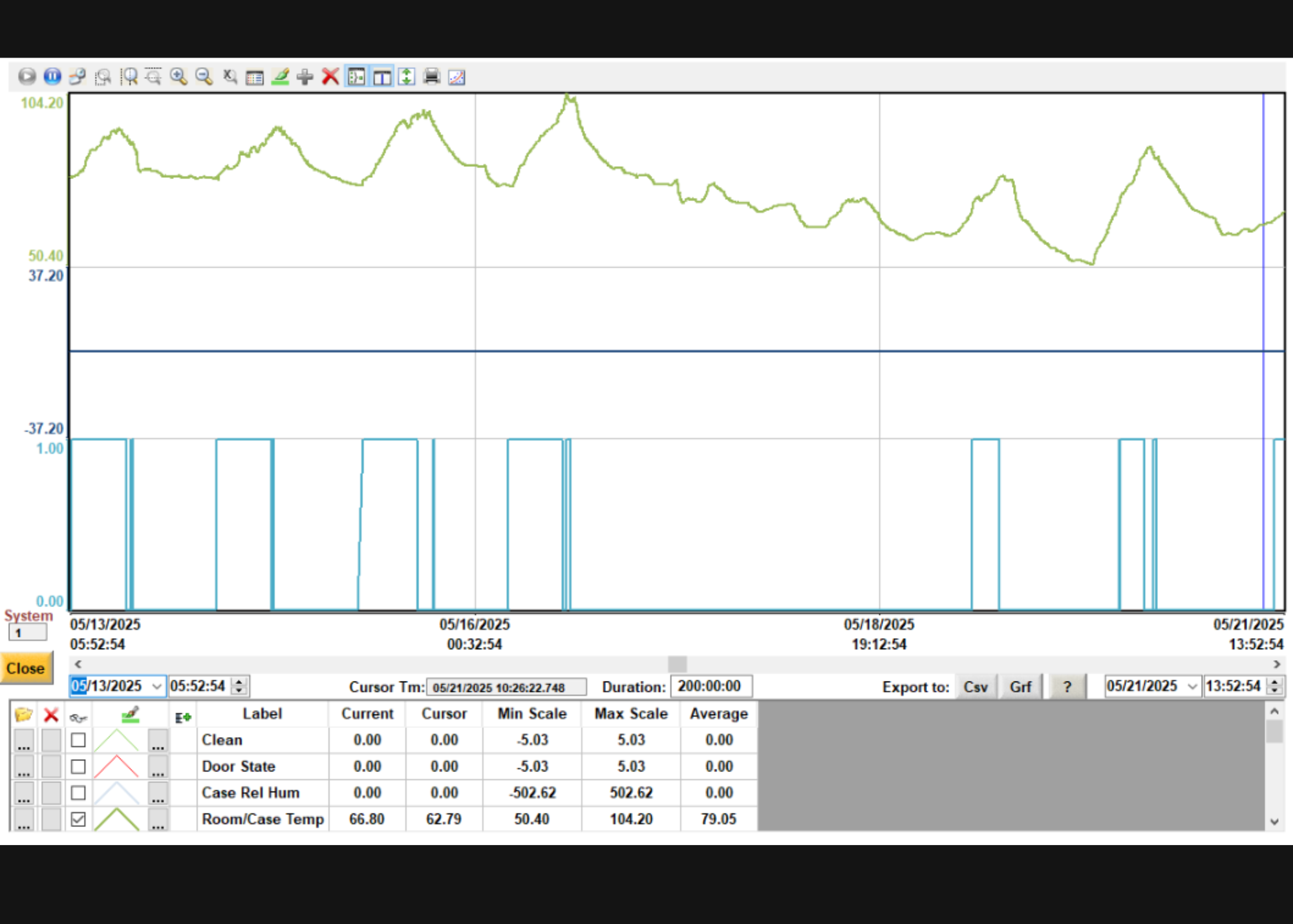

One of the core features of the Sensori Control™ platform is its adaptive compressor management. By monitoring individual compressors' temperatures, pressure, oil level, and oil pressure, we can analyze their performance and efficiency through advanced analyses. Learning from the operating envelope, the system detects deviations from normal or expected behaviour. It proactively requests service before any catastrophic events occur. Additionally, the platform adapts to temperature changes in cases and load profiles, optimizing efficiency by incorporating more sensors for additional valuable information. For instance, knowing how many freezer case doors are open and how long allows the system to adjust the load profile, maintaining temperatures effectively and preventing wastage.

Compatibility:

The Sensori Control™ platform serves as a limitless canvas, allowing the integration of any sensor worldwide, supporting every country's requirements, and boasting major certifications for global compliance. Furthermore, our platform offers unparalleled global support and availability, ensuring users can access assistance and resources regardless of location.

Compressor safety modules within Sensori Control™ are compatible with any compressor manufacturer and can work with various compressor types, providing a comprehensive and flexible solution for all refrigeration needs.

Welcome to the future of refrigeration with Sensori Control™–where innovation knows no bounds.

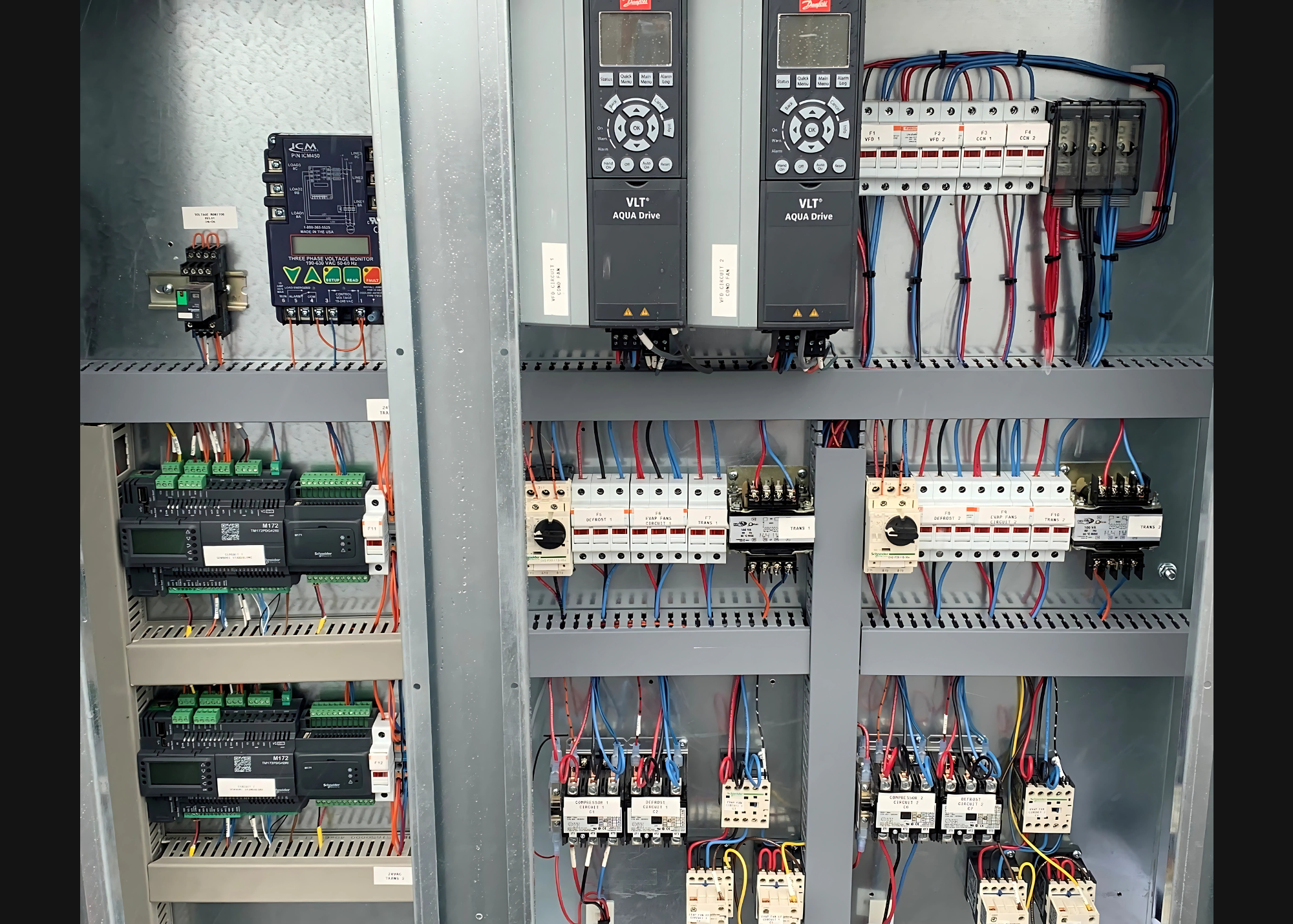

Compressor Safety

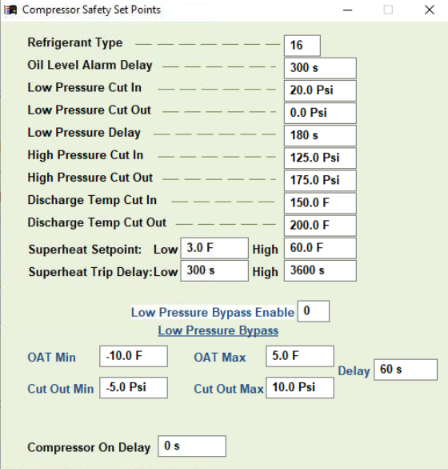

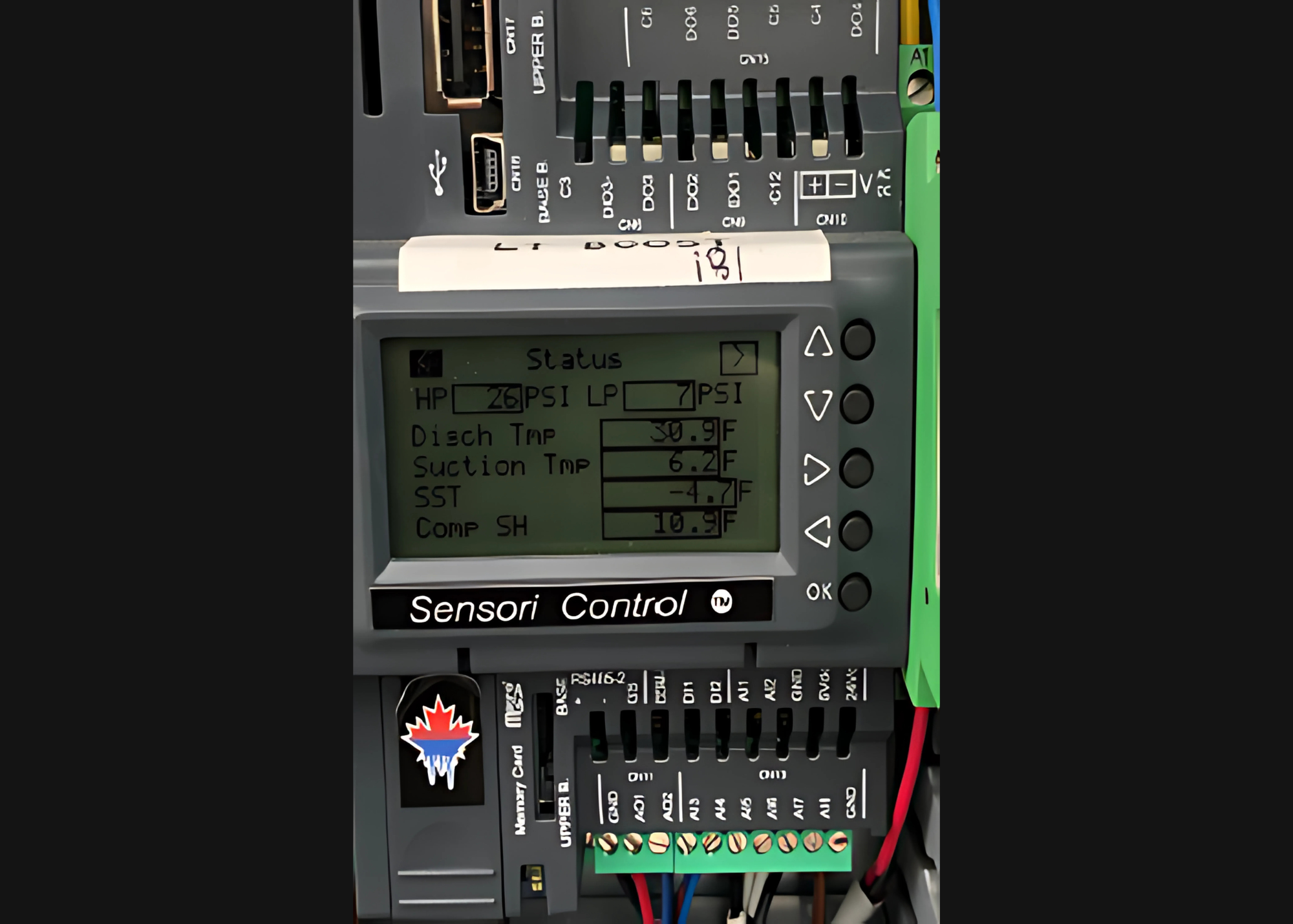

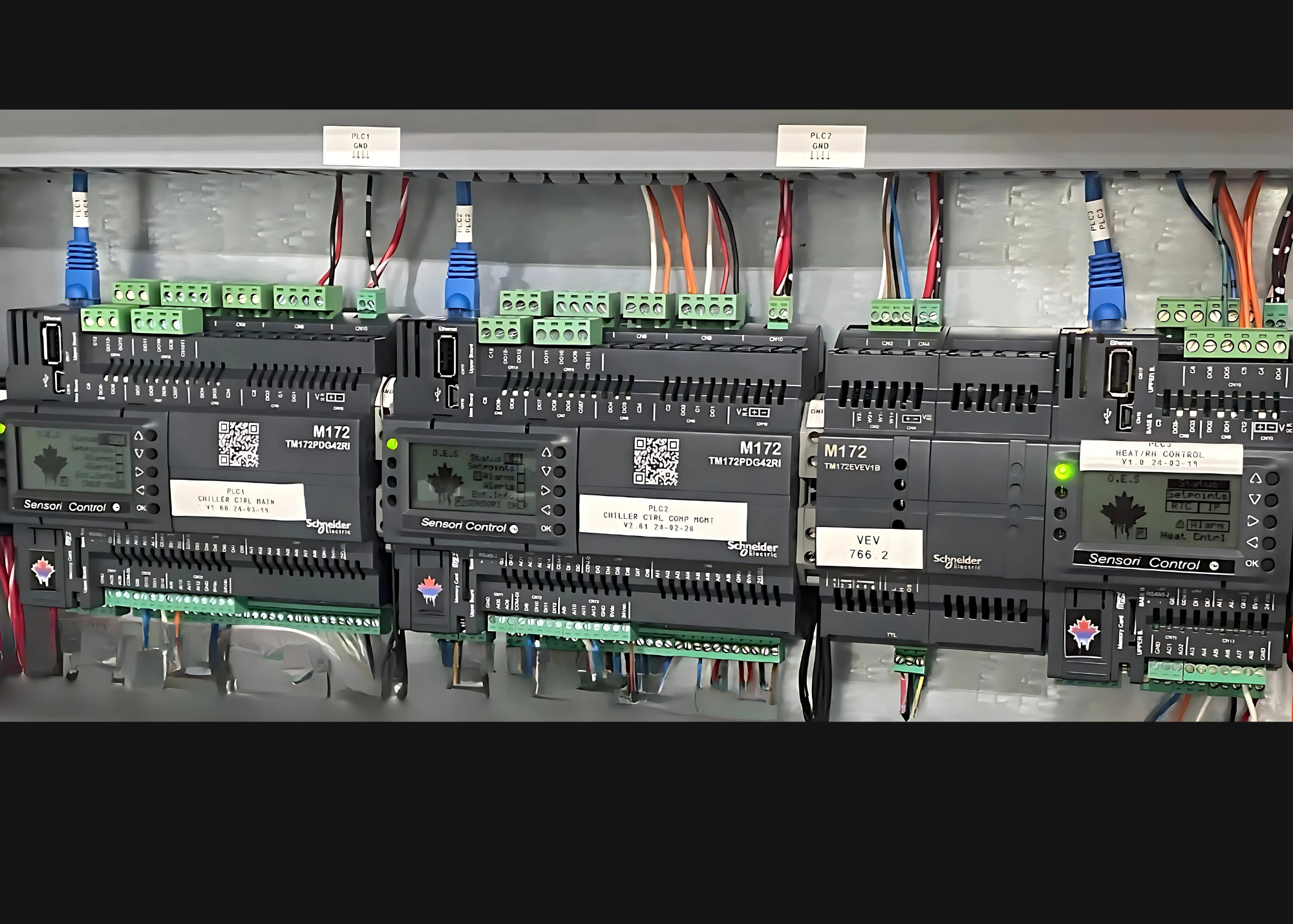

- Autonomous Protection: more...M172 Sensori safety devices function independently while monitoring all critical compressor parameters to prevent failures.

- Real-Time Monitoring: more...Tracks temperatures, pressures, oil levels, and operational status for optimal performance and early issue detection.

- Refrigerant-Specific Optimization: more...Configurable settings support various refrigerants for tailored safety.

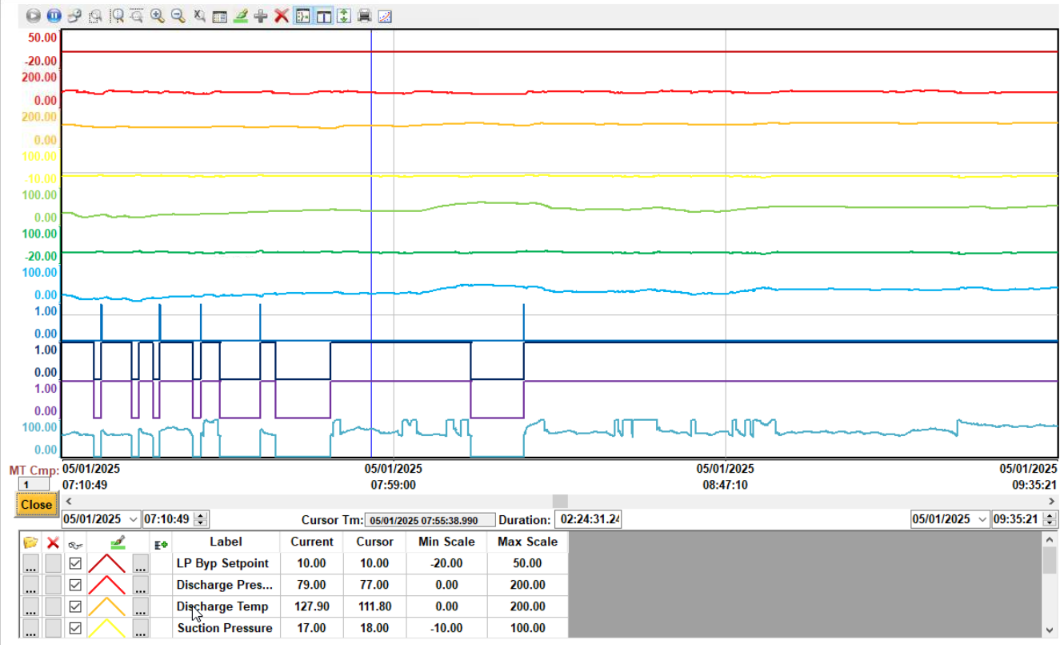

- Performance Analytics: more...Adjustable start/stop delays prevent short cycling, reducing mechanical stress and extending compressor life — while live tracking, graphing, and trend analysis support predictive maintenance and system optimization.

- Operating Envelope: more...Maintains operation within manufacturer-specified temperature, pressure, and superheat limits — replacing all conventional compressor safeties and control platforms to expand protection and optimize performance.

- Customizable Alert System:more...Configurable alarms for all critical parameters notify operators of issues before they become critical.

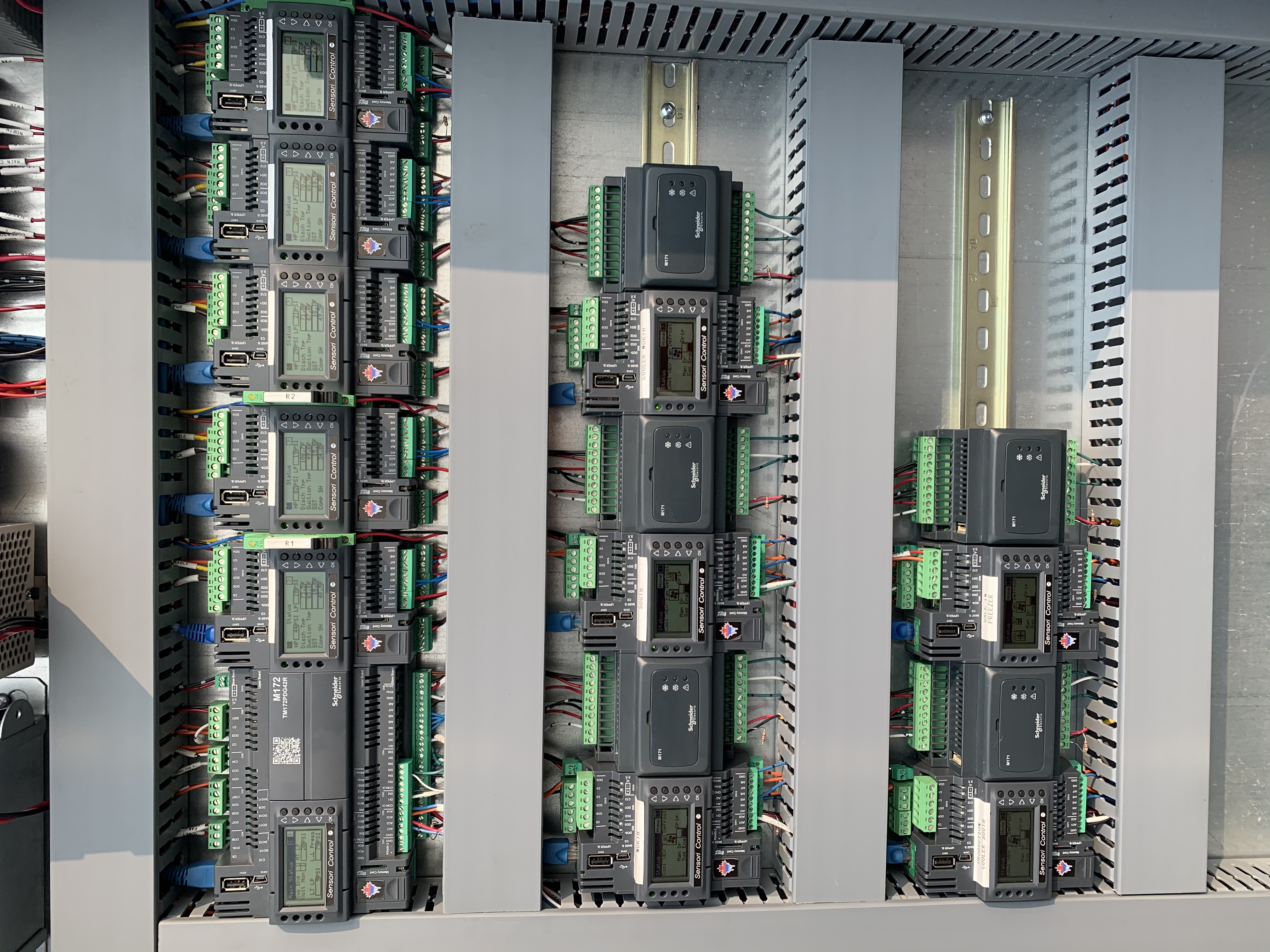

- Integrated Management: more...Complete safety data integration with central management enables coordinated protection across multiple compressors.

- Seamless BAS Integration: more...Ethernet communication with auto-population requires no programming for effortless system monitoring.

Compressor Management

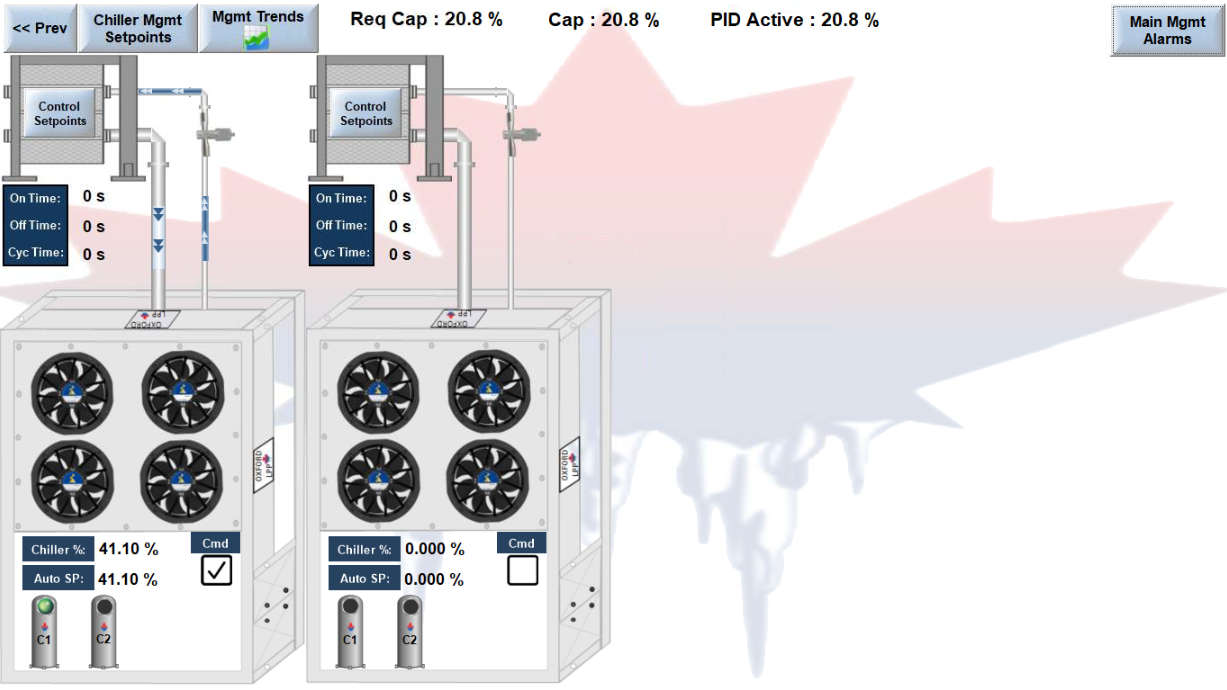

- Precise Compressor Control: VFD drives on MT/LT compressors deliver precise capacity control and eliminate on/off cycling, improving efficiency and equipment life.

- Smart Staging: Advanced PID algorithms optimize compressor staging and ensure reliable low ambient startup, for optimal performance even in challenging cold conditions.

- Dynamic Pressure Optimization: Automatically adjusts head pressure and refrigerant flow based on ambient conditions, ensuring maximum efficiency across all operating environments.

- Comprehensive Safety Monitoring: M172 Sensori devices track critical parameters including temperatures, pressures, and oil levels to prevent failures.

- Seamless Integration: Ethernet BAS communication with SCADA, IPC, GateManager, and HMI interfaces enables zero-programming setup, centralized monitoring, operating envelope visualization, and diagnostics.

- Stand Alone Control: Functions independently without requiring external systems.

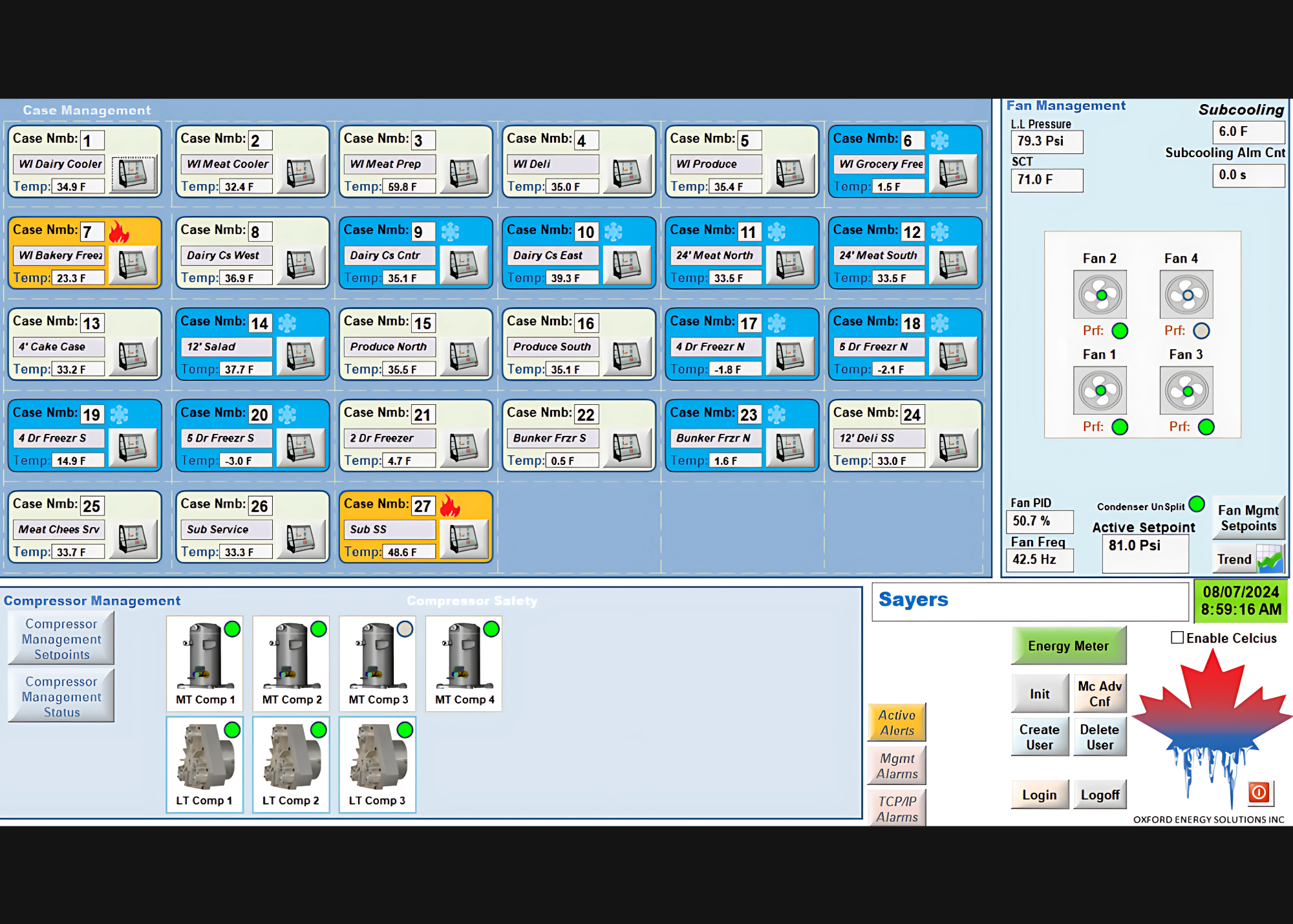

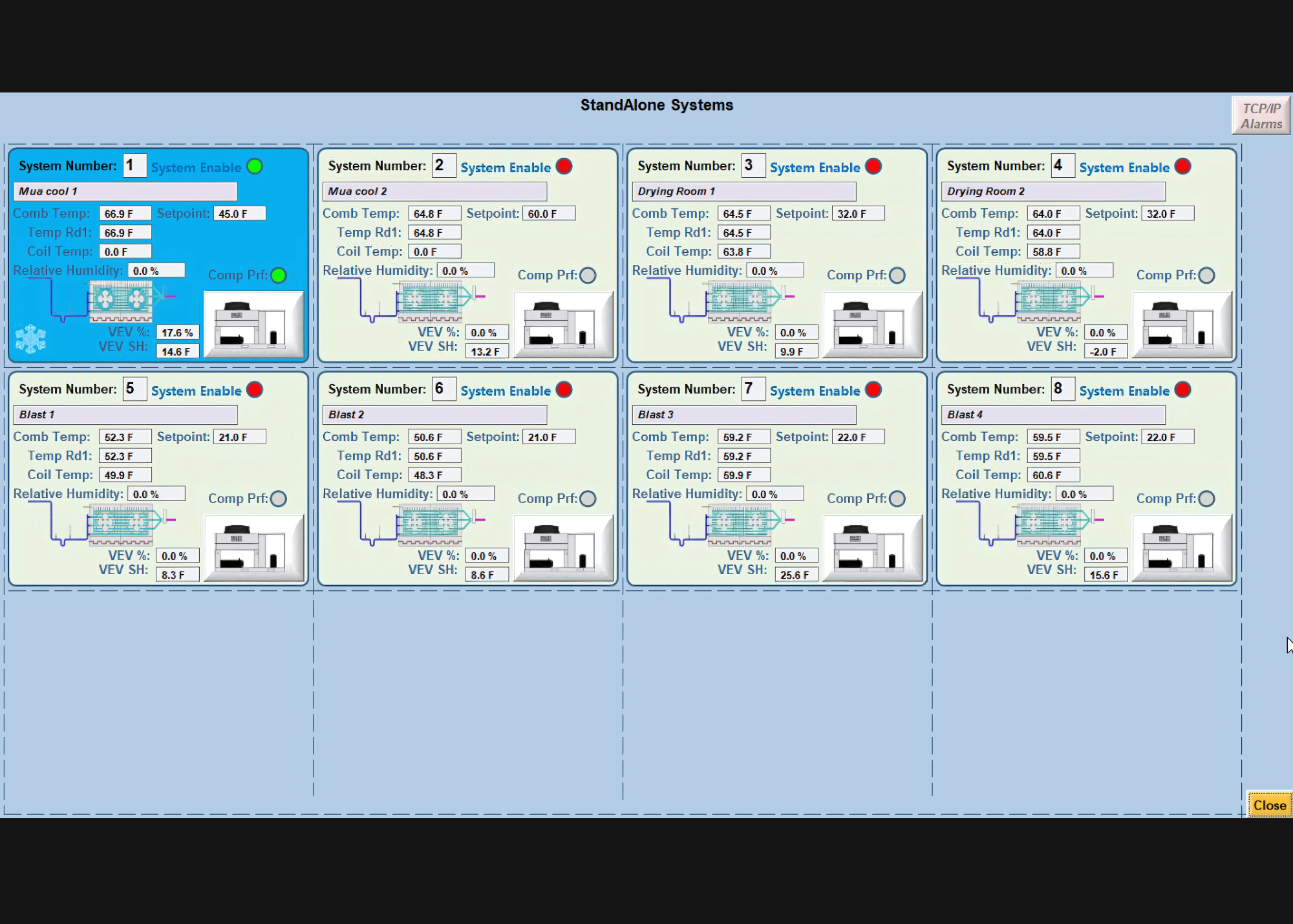

Case Management

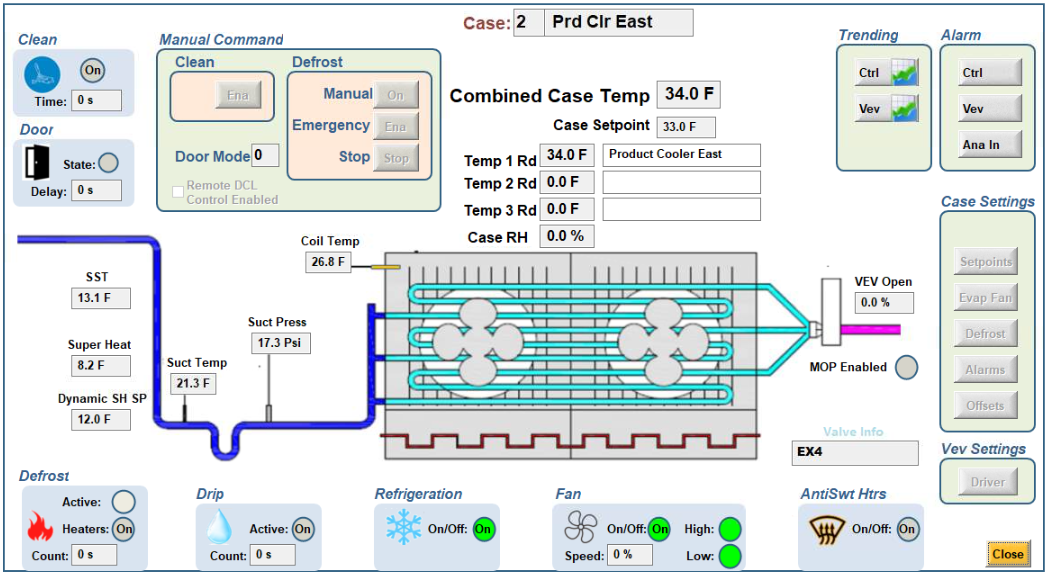

- Advanced Control System: M172 18IO PLC with integrated VEV driver delivers sophisticated automation and precise management.

- Flexible Valve Compatibility: Supports Emerson and Danfoss Bipolar EEV families for optimized refrigerant flow and system design flexibility.

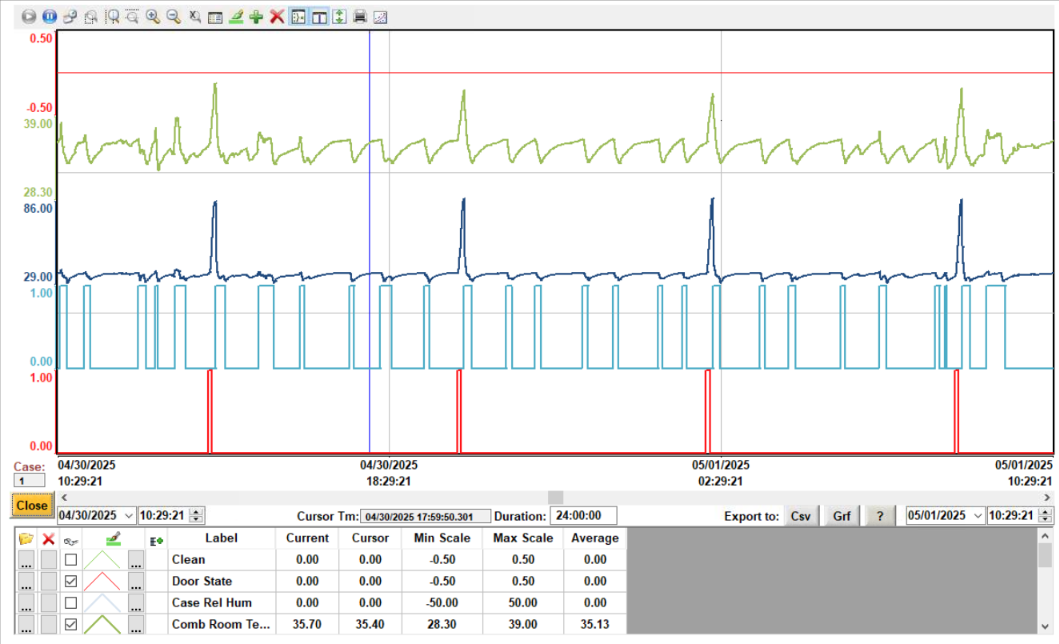

- Data-Driven Insights: Built-in logging and graphing enable performance optimization and predictive maintenance.

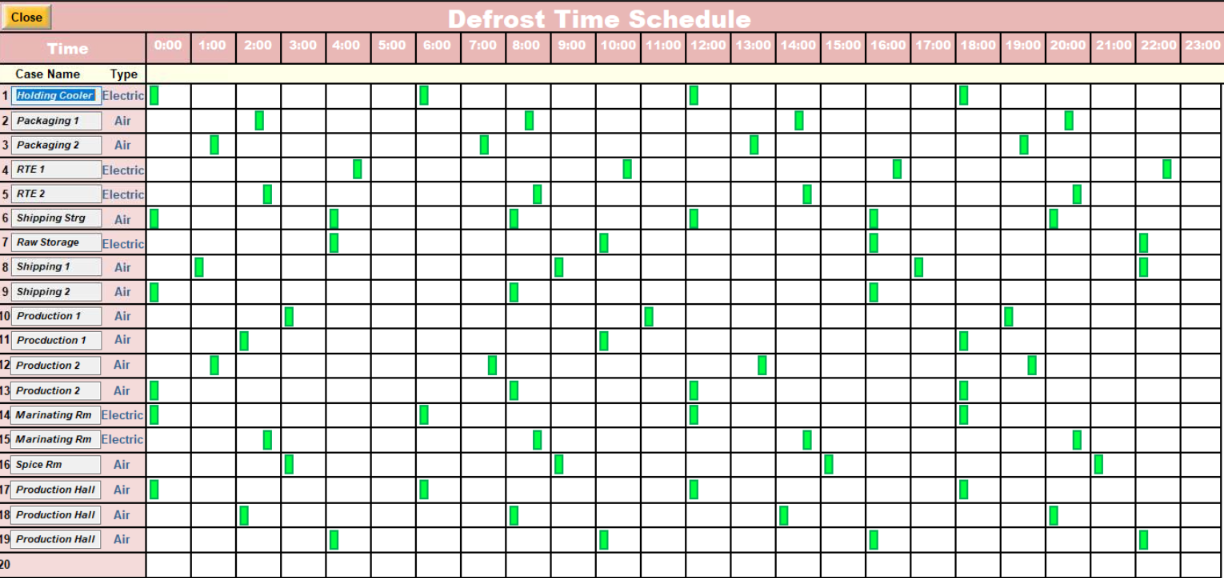

- Efficient Defrost Cycles: Multiple programmable options minimize energy use while preserving product integrity.

- Smart Door Management: Temperature-activated anti-sweat heaters reduce energy waste and enhance visibility.

- Comprehensive Fan Control: Integrated evaporator fan management streamlines operation and ensures coordinated cooling performance.

- Adaptive Climate Control: ECM fans (single, two-speed, or 0-10 VDC modulation) adjust to temp and humidity for peak efficiency.

- Seamless Integration: SCADA, IPC, GateManager, and HMI interfaces provide real-time operating envelope visualization and diagnostics, while Ethernet communication with BAS enables centralized monitoring — no programming required.

- Stand-Alone Control: Operates independently without reliance on external systems.

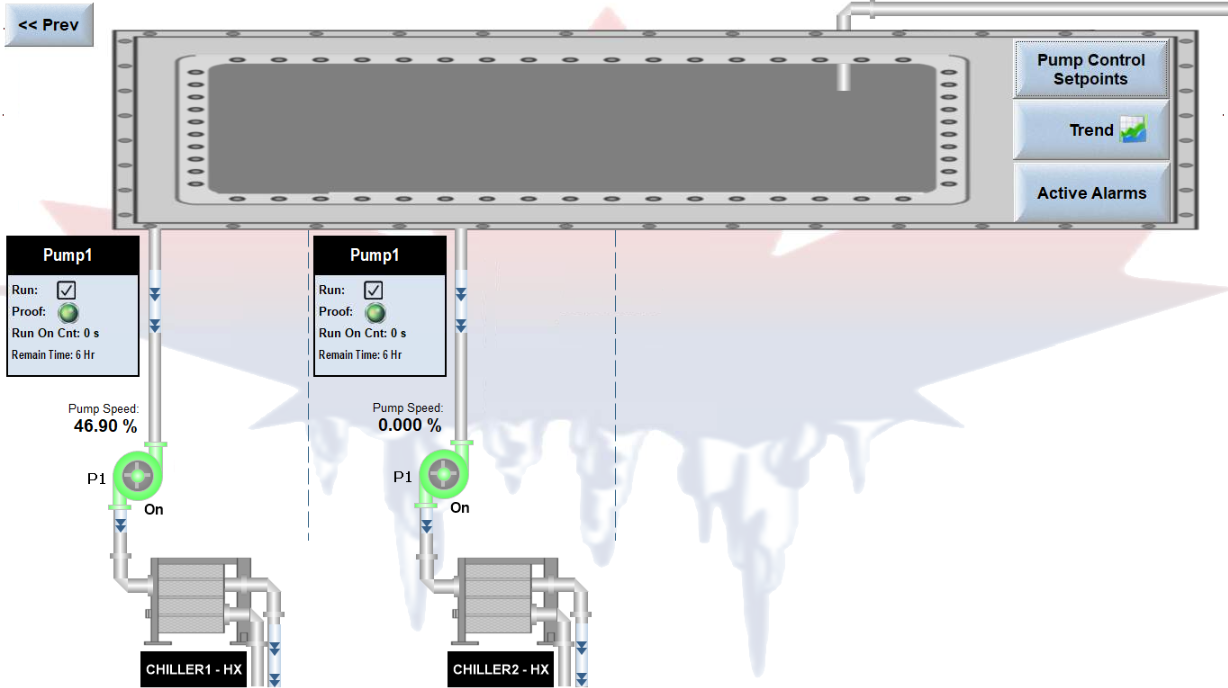

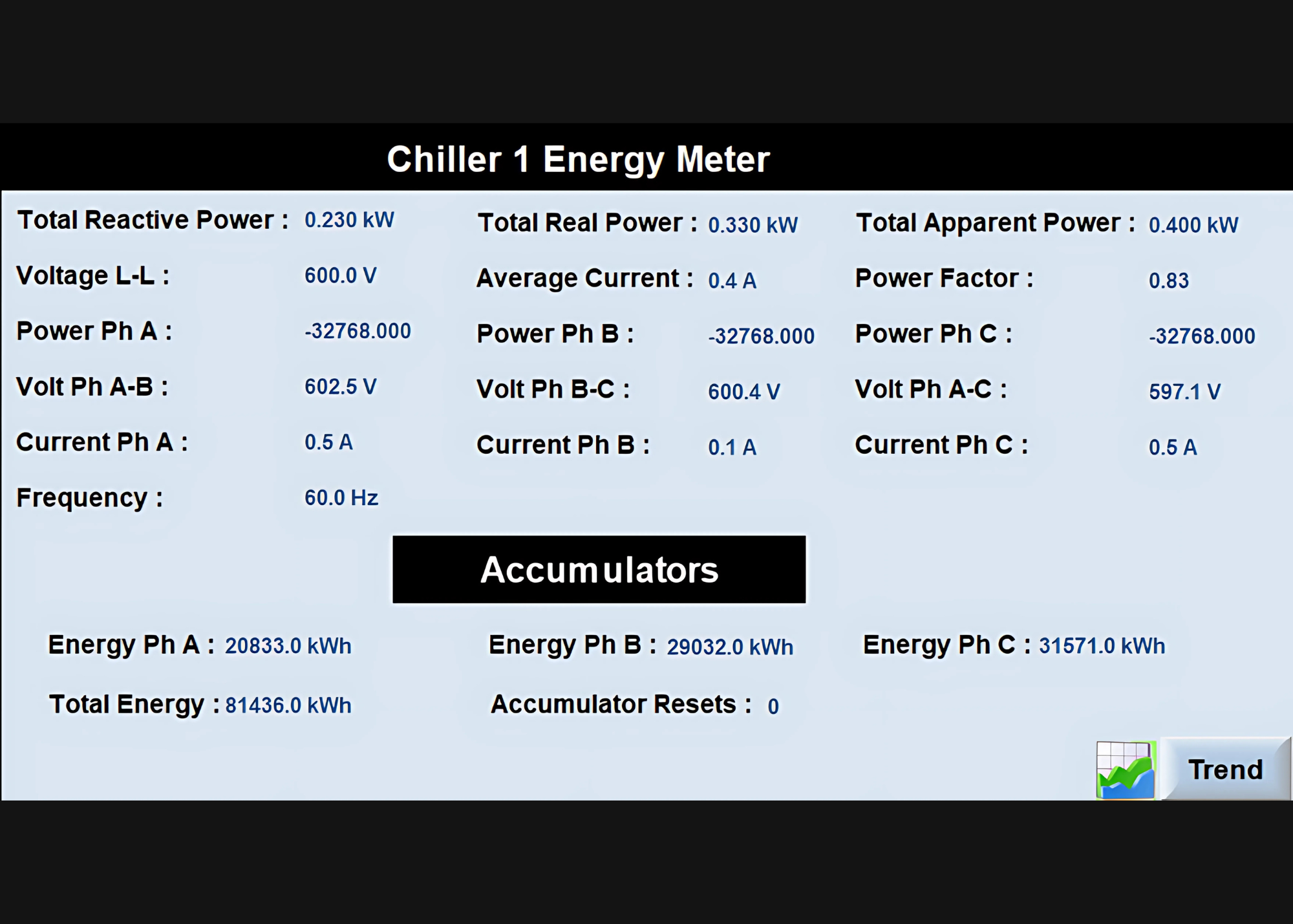

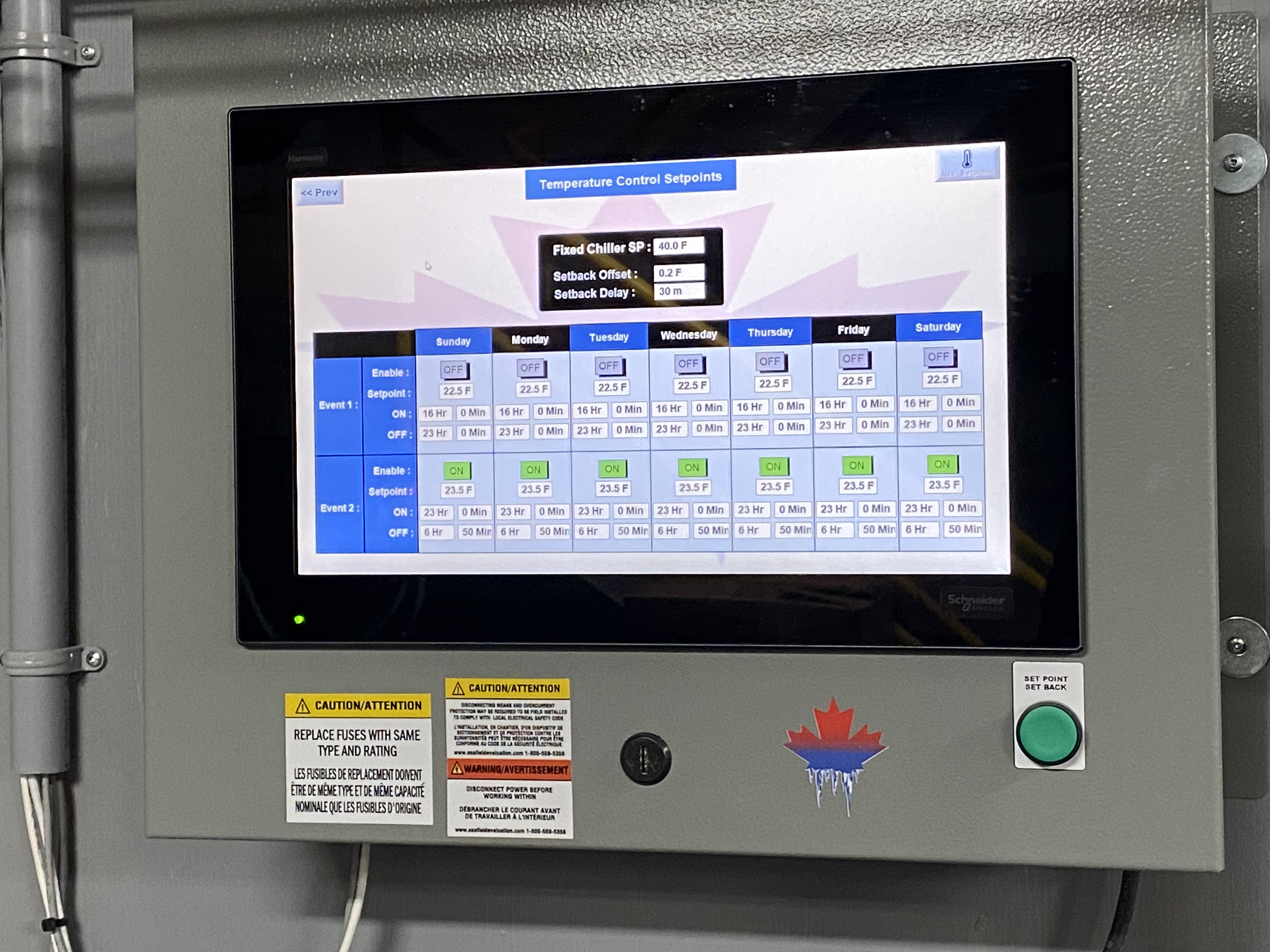

Chiller Management/Pump Management

- Intelligent Circuit Control: M172 42 main controller delivers precise temperature-based management of all chiller setpoints through sophisticated circuit-by-circuit control.

- Advanced Pump Optimization: Comprehensive management of up to two pumps per chiller with VFD speed control ensures maximum efficiency and reliable redundancy.

- Specialized Surface Control: IFR sensors ensure precise slab temperature regulation for demanding applications like ice rinks.

- Flexible Operation Modes: Temperature shift control based on schedules, manual inputs, or steady setpoints allows perfect adaptation to changing operational requirements.

- Seamless System Communication: Seamless Modbus connectivity enables full BMS integration for monitoring, control, and energy efficiency.

Standalone

- Advanced M172 Platform: Combines 18IO PLC with integrated VEV driver for case management and Sensori safety monitoring in a single streamlined system.

- Comprehensive Monitoring: tracks temperatures, pressures, oil levels, and system status.

- Adaptive Climate Control: ECM fan technology with variable speed control automatically adjusts to real-time temperature and humidity conditions.

- Optimized Defrost & Door Management: Programmable defrost cycles and temperature-activated anti-sweat heaters minimize power consumption.

- Refrigerant Flexibility: Configurable settings support various refrigerants.

- Predictive Maintenance: Comprehensive data analysis with built-in logging, graphing, and trend analysis.

- Integrated Safety & Alerts: Customizable alarms and operating envelope enforcement ensure reliable operation.

- Seamless BAS Integration: Ethernet communication enables instant, programming-free connection to building management systems for unified monitoring and control.

- Independent Operation: Stand-alone control capability functions without requiring external systems.