A growing number of modern dairy farmers are developing innovative diversification strategies with the increasing popularity of on-farm dairy processing. Supported by the rising consumer trends of buying locally sourced goods, shortening the food supply chain presents sustainable and economic benefits for farmers and communities. Harvesting, processing, and marketing products on-site with direct-to-customer sales put farmers in greater control of their products, profits, and sustainability goals. Advanced technology helps a transforming dairy industry attain the efficiency that sustains family businesses for future generations.

2022 SAW THE STAGES OF DEVELOPMENT AND OPENING OF SEVERAL SMALLER-SCALE ON-FARM PROCESSING PLANTS IN SOUTHWESTERN ONTARIO

Mistyglen Creamery (Elgin County)

For Mistyglen Farms, a small dairy farm near Belmont, Ontario, the Creamery has been a new addition to their family farming business established in 1957. Suzanne, Tom, and Kris, Pettit have diversified

their farming business by integrating agricultural/beef production with dairy processing and direct-to-customer sales. The Creamery offers fresh farm products made on location and other local and

artisanal goods. As modern consumers emphasize the content, origin, and freshness of food and its sustainable production, the Pettit family designed a way for the community to

become involved and experience the process. On-farm dairy processing allowed Mistyglen to extend its business, connect locally, offer nutritious products, and share its farm-to-table story.

Golspie Dairy (Oxford County)

Northwest of Woodstock, Golspie Dairy embraced versatility and adaptability to transition their family business to sustain their 150-

year farming tradition for the next generation. Marja DeBoer-

Marshall and Laurence Marshall combine on-farm micro-processing

and retail as an alternative to purchasing land or additional milk

quotas to expand business operations. The venture generates other

revenue streams that strengthen the farm's financial stability and

continuity. The direct sales of their home-

sourced goods allow Golspie Dairy to offer the freshest products, have greater control over their supply chain, and

generate a fair return as producers. It lets them engage, provide quality products for the surrounding community,

and meet the increasing demand for locally produced sustainable goods.

Modern Dairy Farming Enhanced by Today's Refrigeration Technology

Refrigeration is fundamental in processing healthy, first-rate dairy products. Guaranteeing the stability of refrigeration equipment is essential since the failure of any part of the system risks disastrous results. Strict tolerances for proper refrigeration are required through every step of processing. Milk requires immediate cooling before and after pasteurization to minimize the risk of bacteria growth. Complete temperature control is necessary to ensure products are safe to consume, preserve quality and composition, and extend shelf life.

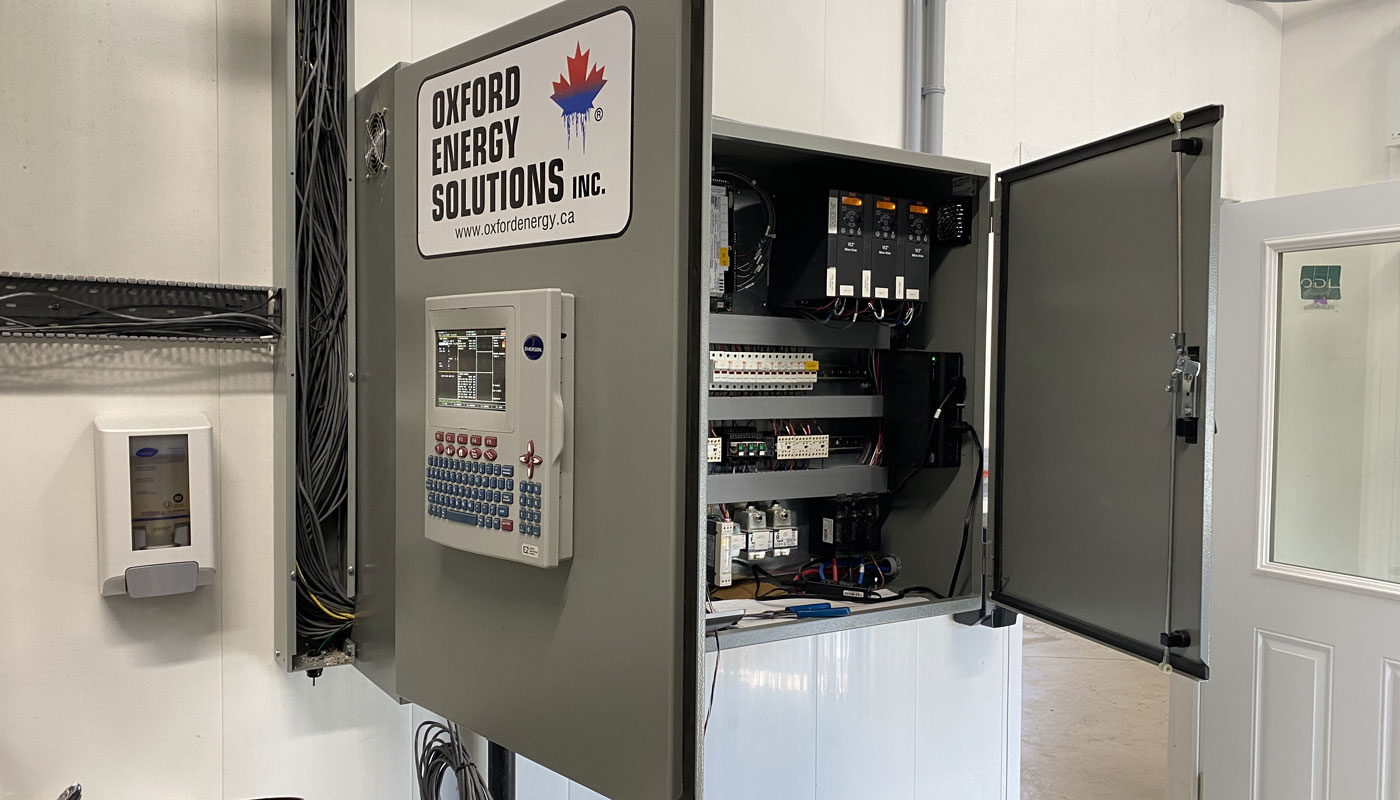

Today's technology enhances modern dairy farming and gives farmers complete control over their operations with better efficiency. Oxford's fully modulating condensing unit with digital monitoring provides a flexible, integrated platform that regulates equipment performance. Electronic regulation enables precision control of every device in the system.

Oxford County's Gunn's Hill Cheese and Stonetown Artisan Cheese in St. Mary's are trailblazing processing plants that have longevity with Oxford's advanced system management. Having become staples in their communities, the companies manage their facilities with automation, saving time, labour, and energy. Automated control lets them use a combination chiller/ac system and alternate between chilling and cooling, according to requirements. They benefit from a high-quality infrastructure while saving on capital costs.

Complete system governance is established with Oxford's Building Automation System – BAS (SensoriTM/E2). It gives processors access, control, and monitoring capabilities to see how their equipment performs during processing and storage. With the combination of intelligent controls, electronic components, and digital management, Oxford's automated control provides stringent temperature regulation and comprehensive real-time data. Through an HMI, they can visualize and manage the temperatures of raw milk as it enters the pasteurization process, cools, and is stored. They can intervene and adjust the system locally and remotely to prevent issues. The ability to follow the product through every stage and verify the optimal operation of the system provides confidence that milk has maintained safe temperatures and the best possible characteristics.

The Efficiency of Plate Heat Exchangers in Pasteurization

High Temperature – Short-Time (HTST) processing is the industry-standard choice for more extensive facilities. However, for small-batch dairy processors, vat pasteurization is a suitable and gentler way to refine milk that maintains healthy bacteria and product characteristics. While being a slower process, using lower temperatures preserves the high quality that on-farm processors aim to market. As dairies expand production to include additional products, the time it takes to pasteurize and cool milk affects productivity. However, increasing the temperature during pasteurization to speed up the process can risk the composition and flavour of the product.

Unlike cheese, where pasteurized milk is cooled to approximately 32-34°C before processing begins, fluid milk requires much lower temperatures. Oxford's combination of a chiller and secondary plate heat exchanger plays an essential role in delivering efficiency in batch processing fluid milk. It is one of the most effective methods of quickly managing product temperatures and reducing the energy costs of cooling/heating for dairy processors. Pre- cooling or preheating milk decreases the time it takes to achieve optimal temperatures for pasteurization and storage. It reduces the risk of unwanted microbial growth and the energy required to reach proper temperatures.

As milk passes alongside one plate, pumped fluid (i.e., water/glycol) moves along the alternate side of the heat exchanger's compressed stainless-steel plates. The cold fluid absorbs heat from the warmer milk as the liquids pass across the separating plate (which acts as a conductor). Likewise, milk temperature can be increased similarly by passing hot fluid past the steel plates. The cooler milk absorbs heat before pasteurization, reaching ideal temperatures in a fraction of the time typically required.

Processors can use a Regen Plate system with the heat exchanger to take advantage of additional time and energy benefits. In this sequence, the returning pasteurized milk passes through as cold raw milk flows inversely to be processed. The heat exchange quickly gets the product closer to he required temps, leveraging the 'free' cooling/heating. The energy and time needed for the processing are drastically reduced, resulting in a 60% reduction in the energy required to process the product. The heat exchange sequence allows batch processors to have a premium product and accomplish it at the same efficiency levels as those with HTST pasteurization.

Stewards of the Land

As stewards of the land, farmers are acutely aware of the impact of their products and processing on the community, environment, and businesses. Processes must be sustainable and profitable simultaneously. Protecting resources and reducing an environmental footprint benefit their long-term business continuity. On-farm dairies have several opportunities to achieve production efficiency and define sustainability goals by managing energy and water consumption and directing their supply chain.

Food production is energy and water intensive. Equipment sanitation is a continuous process throughout the day. Often there is significant water and power waste, leaving high costs and environmental impacts. It is essential to manage CIP (cleaning-in-place) systems well. Oxford's integrated management maximizes the efficiency of multiple steps within the process, allowing all devices in the system to be washed in one loop. It reduces CIP schedules, saving processors resource input, time, and money. Precise control maximizes efficient water and energy use as part of the internal production process.

On-site dairy processing allows farmers to be decision-makers and control the process rather than having their milk travel out of the county to a different processor. Dairies govern their supply chain every step of the way – from what they produce to how they are packaged and distributed. By reimagining the family farming business, they cultivate a sustainable path that positively impacts the community, environment, and profitability. For modern dairy farmers, combining diversification strategies with technology can provide unique opportunities to expand the market and sustain businesses for the long term.