Throwing stones across a frozen pond has morphed into an internationally renowned sport of curling, a refined game of strategy and endurance. Modern curling competitions take place in carefully controlled conditions indoors, where ice specifications are of utmost importance. For Curlers, ice conditions are critical to game strategies – and for clubs, it significantly impacts the quality of services they can offer their members.

Often run as non-profit entities, local clubs rely on their patrons' contributions through membership fees and fundraising to cover operational costs. It can be difficult for many clubs with restricted budgets to handle the expenses associated with outdated refrigeration equipment. When replacements are imminent, clubs must evaluate the system's total impact on the cost of ownership and sustainability when considering the best refrigeration for a facility.

AYLMER CURLING CLUB, NORWICH DISTRICT CURLING CLUB, PARIS CURLING CLUB

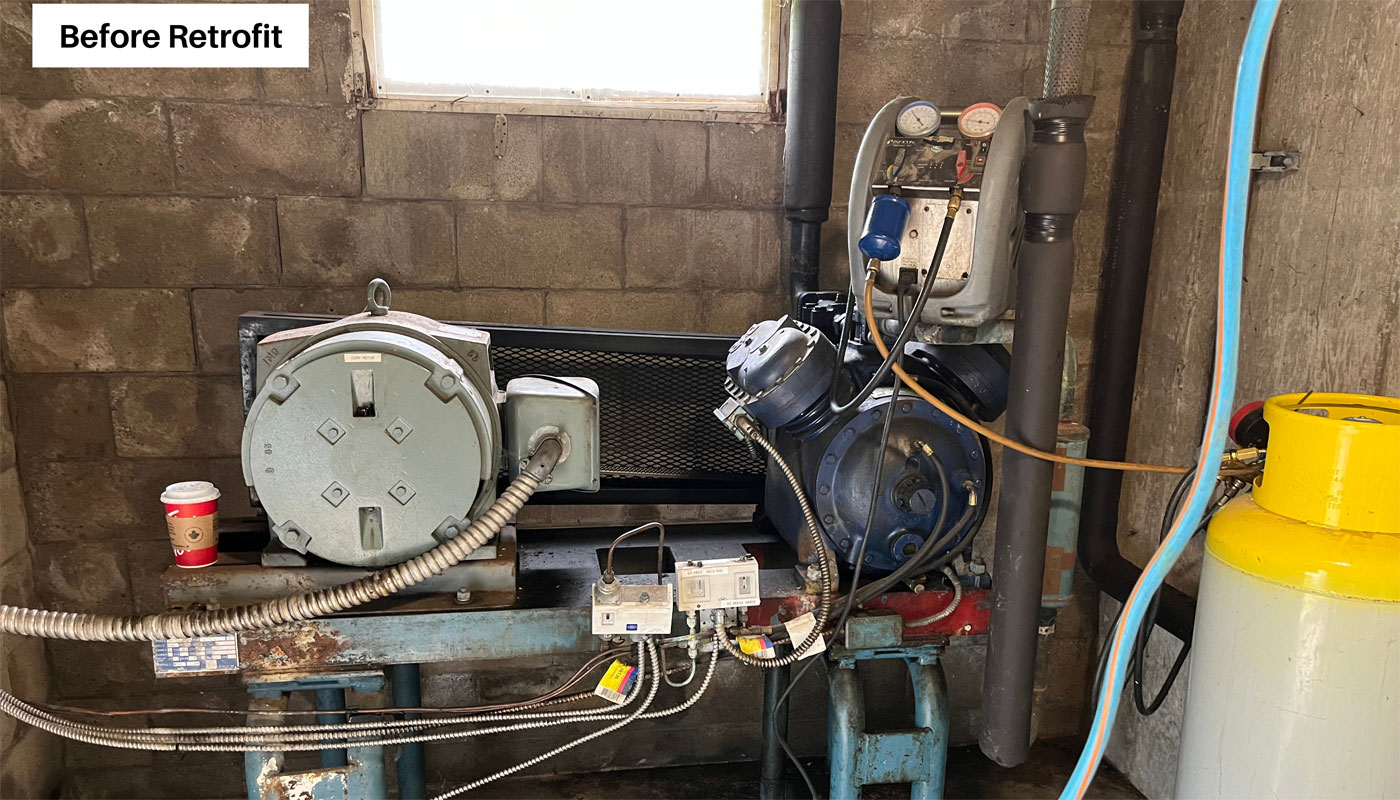

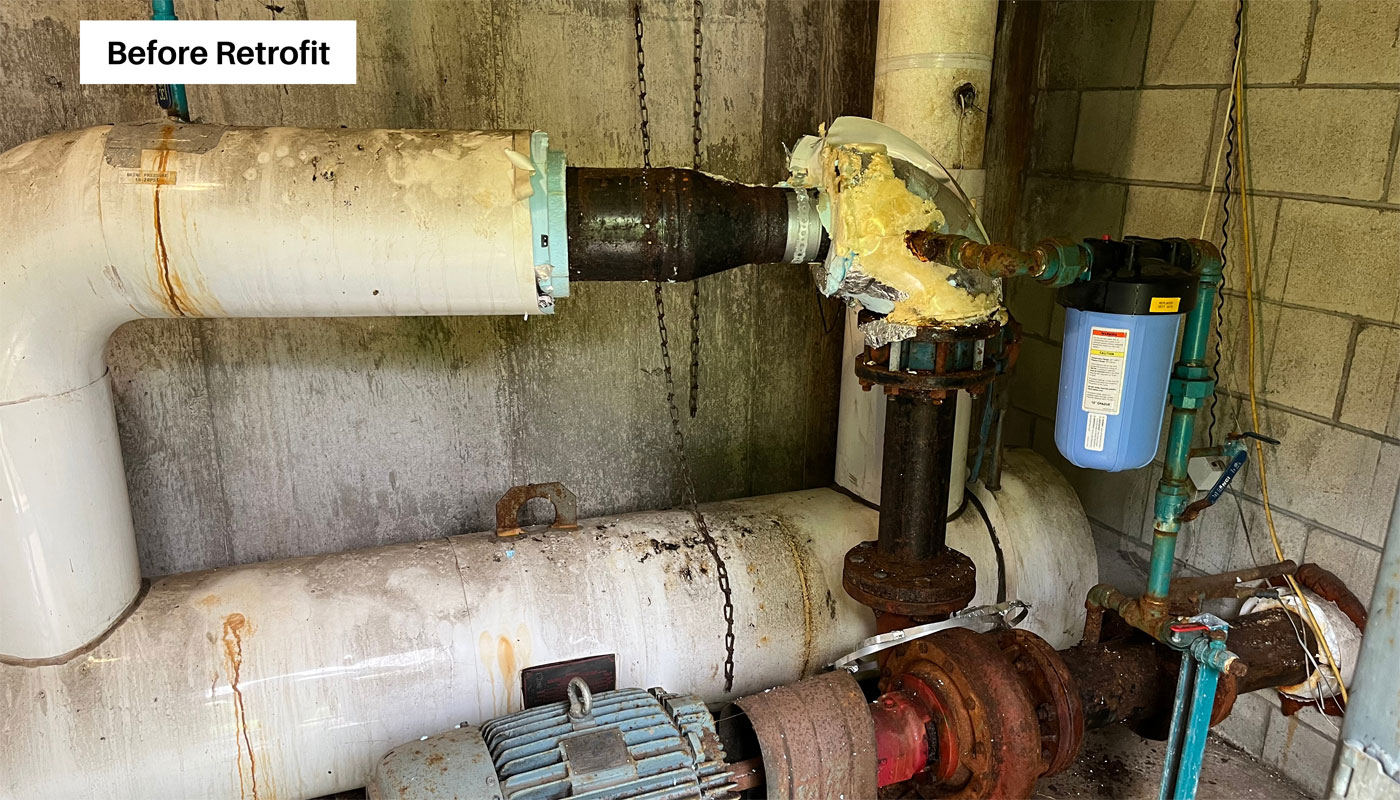

A common theme among most clubs is the aging equipment they operate with, often associated with higher risk levels and safety issues. The high replacement costs make it challenging to re-invest when the proposed new equipment is the same as what they already use, with fresh paint. There have been few substantial advancements in the past 30-50 years (the average equipment age requiring updates).

High energy use and frequent servicing due to increased mechanical failures leave clubs with crippling costs. The club in Paris struggled with electricity costs of over $36,000 annually. Repetitive failures kept Aylmer's ice maker, Mark Phillips, continually policing equipment, costing the club over 7 thousand dollars in parts and labour in the 2021-2022 season. Ever- increasing maintenance costs were draining resources at Norwich District Curling Club. The facilities needed reliable equipment and reduced energy consumption that was more manageable and decreased their environmental footprint.

Each club needed to consider short- and long-term projections when facing upgrades. They needed systems that addressed immediate mechanical and energy issues and offered the flexibility for affordable future upgrades. Safety concerns negate any consideration for flammable, highly toxic, or high-pressure systems (Ammonia/CO2). Systems requiring special training, materials, and extensive safety measures, leave a confidence gap in managing equipment, risk the safety of members, and deplete already strained resources. Replacing equipment with designs that lacked control measures would not sustain the clubs' maintenance or energy reduction goals. Platform architectures that require complete system changes and lack flexibility for future retrofits (Ammonia and CO2 systems) are not financially feasible. Retrofit options with total system management offered the facilities incremental steps toward a solution they could implement immediately to support the clubs for years.

GAINING CONTROL

Many things can affect ice conditions in Curling clubs, from the friction of the rocks moving down the pebbled surface to the number of players/spectators in the facility. The type of building, its age and design, location, and climate are diverse and affect how hard refrigeration equipment must work. Ideal ice conditions require constant monitoring, adjusting temperatures, and maintaining humidity levels to ensure the quality of the playing surface is consistent.

Ice makers need uncomplicated system management without additional complexities or hidden costs. They need straightforward strategies that provide insight into what machines are doing and whether they are doing it well. Reactive servicing is the norm without seeing what is happening inside the system and how it performs; troubleshooting and excessive supervision/labour become the method to avoid mechanical failures. Technicians shouldn't be at the mercy of the equipment they manage – with guesswork or getting service calls in the middle of the night. Visualizing how a system operates is crucial for optimizing performance and protecting equipment.

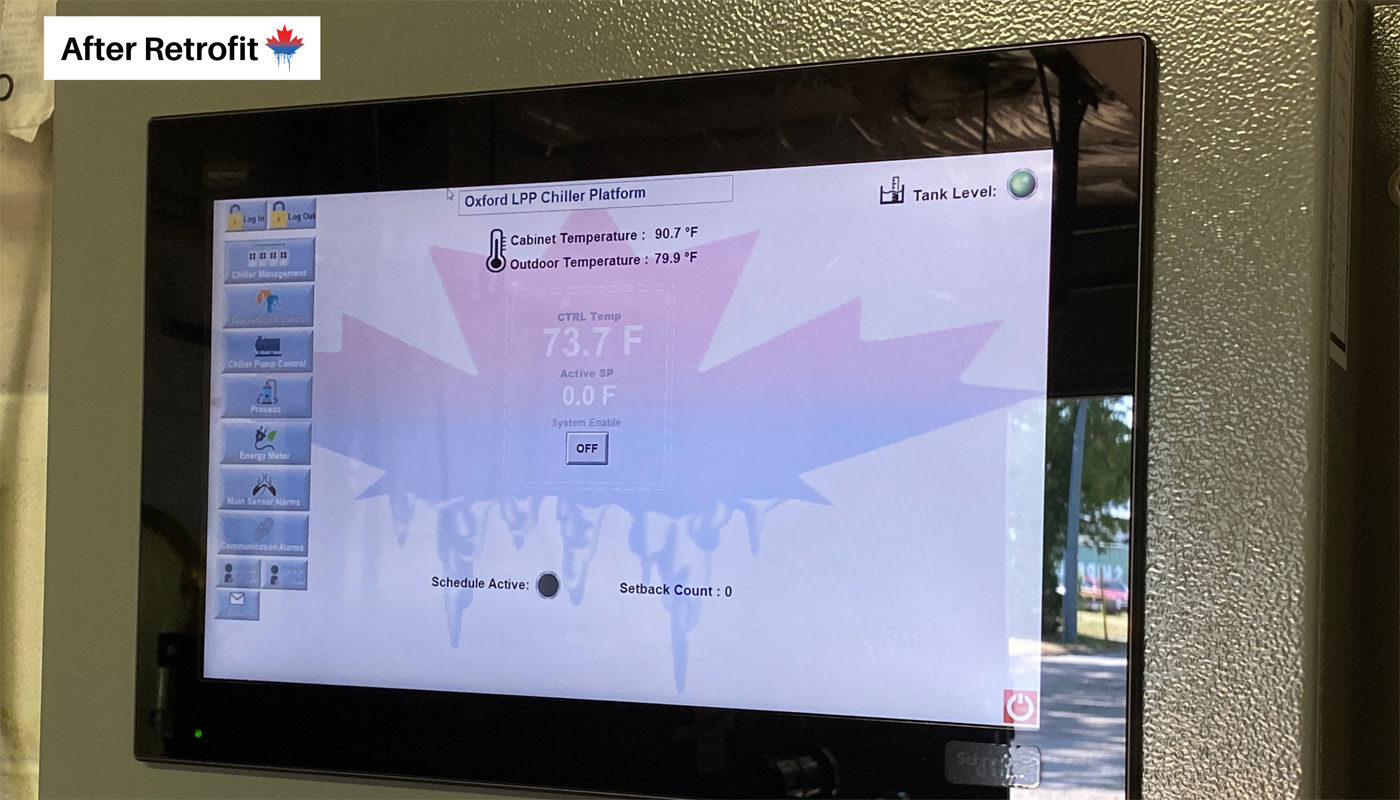

Built-in system management with Oxford's Building Automation System – SensoriTM Chiller Platform connects and electronically regulates all devices in the system. Components incorporate the data generated by other devices and synchronize to determine performance. A central HMI screen offers complete transparency, showing temperatures, pressures, and oil levels and how these affect the system's operation. Being able to see everything in the system with readily available graphing/logging capabilities reduces the monitoring needed by technicians. The platform is IoT-controlled, with remote accessibility and alerts. Ice makers receive notifications of inconsistencies, allowing them to respond proactively to any event affecting operating costs, equipment management, or ice quality. With comprehensive information, Oxford's system management alleviates the emergency response to issues that become critical due to the lack of insight.

QUALITY AND SAVINGS WITH ADAPTIVE MANAGEMENT

Maintaining ice quality in unseasonable warm conditions or during a busy bonspiel can be energy hungry without the proper control. As changing temperatures and indoor activity impact the heat accumulating in arenas, the refrigeration system must respond to varying demands. The compressor's capacity and efficiency govern how well heat can be drawn from ice.

Systems that cannot automatically accommodate the load turn compressors on/off to control ice temps or attempt to save energy during unoccupied periods. Unnecessary temperature swings with inconsistent ice are the result. These compressors operate with fixed head pressures that force equipment to run at the maximum output - regardless of the ambient temperature or cooling demand.

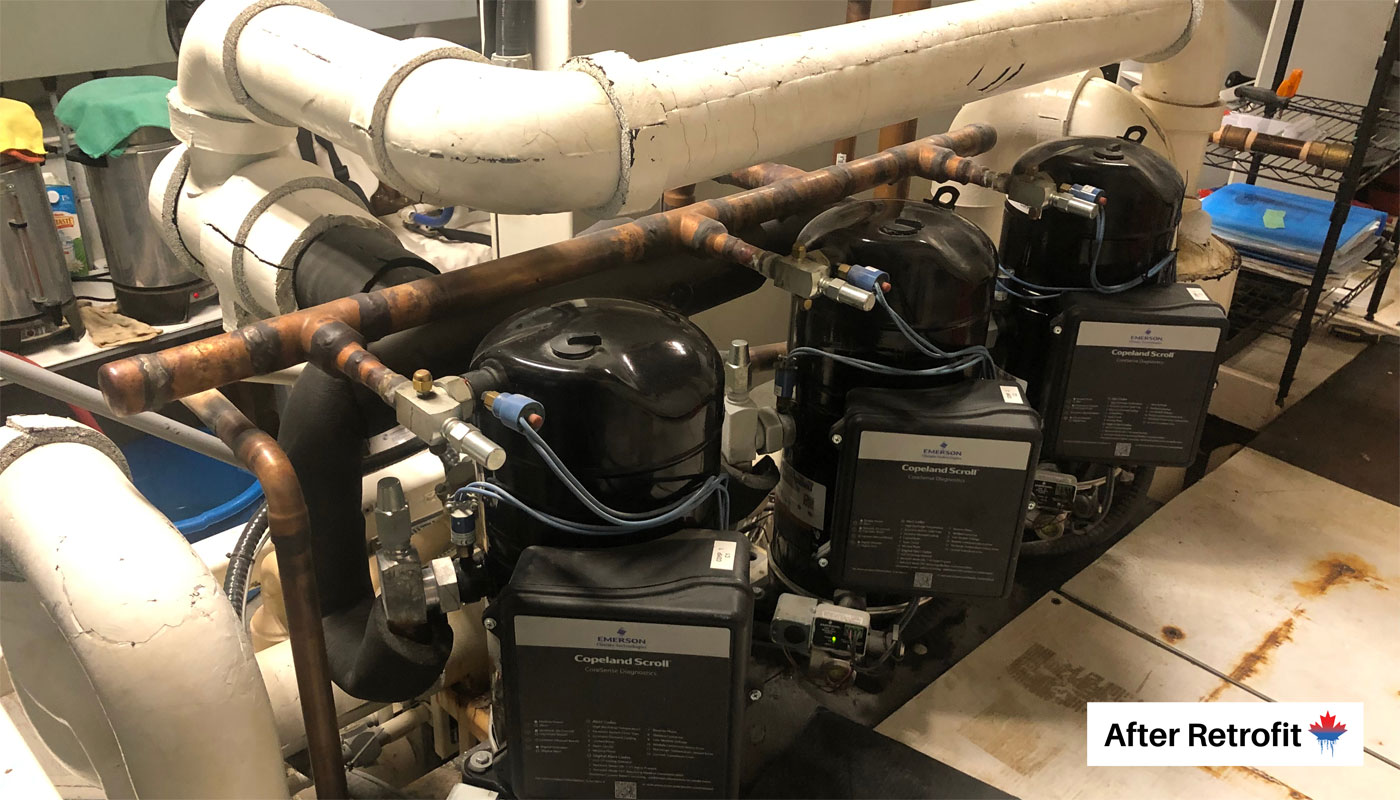

Oxford's platform responds symbiotically to changing elements with varying head pressures and adaptive compressor management. Through the automation system, variable frequency drives (VFDs) enable the brine pump, condenser, and compressors to adjust performance based on sensor-gathered data to accommodate changing conditions. The reduced compressor on/off cycles and improved temperature delta across the evaporator smooth the ice temperature swings to less than 1°F. The capability to fluctuate refrigeration with demand results in less mechanical stress and energy savings – regardless of occupancy. Replacing large, energy-hungry compressors, multiple smaller scroll compressors operate based on the cooling capacity needed and deliver redundancy for system reliability and protection. Should a compressor experience inefficiency, the system automatically switches to another and sends email notifications to alert technicians.

FLEXIBILITY ELEVATES THE INVESTMENT

Oxford systems, operating with low pressures and low flammability/ toxicity refrigerants, do not require any special mechanical room features or infrastructure changes. Less intensive piping and eliminating unnecessary parts allow small, quiet compressors to fit easily into previously overcrowded mechanical rooms. The reduced architecture with fewer complexities delivers less waste, and the outdoor condensing unit provides greater flexibility, with future relocation as an option.

SUSTAINABILITY DETERMINES SUCCESS

When facing equipment upgrades, clubs determine their success and continuity through sustainable choices. Explicit knowledge of what is running the system, what went into creating it, what it is consuming, and its impact on the community and environment, is crucial. With conventional refrigeration platforms, clubs carry the extra weight of overly congested systems with additional inputs and hidden costs (i.e., safety measures and resource consumption). The green-washing of 'natural' refrigerants conceals the energy- intensive industrial manufacturing processes that keep us from reaching climate goals. Systems that lack advanced control measures deliver yesterday's inefficiencies.

When technicians have confidence in the safety of their equipment and clear, concise information about their system's performance - they gain control and are better able to manage facilities. Systems with integrated energy profiles and automated management reduce consumption, safeguard equipment and resources, and provide a quality experience for patrons. A club should have high expectations, demand transparency with its investments, and consider the total cost of ownership. Systems that are safer and better mechanically, architecturally, and environmentally will have financial benefits and offer the longevity needed from equipment.