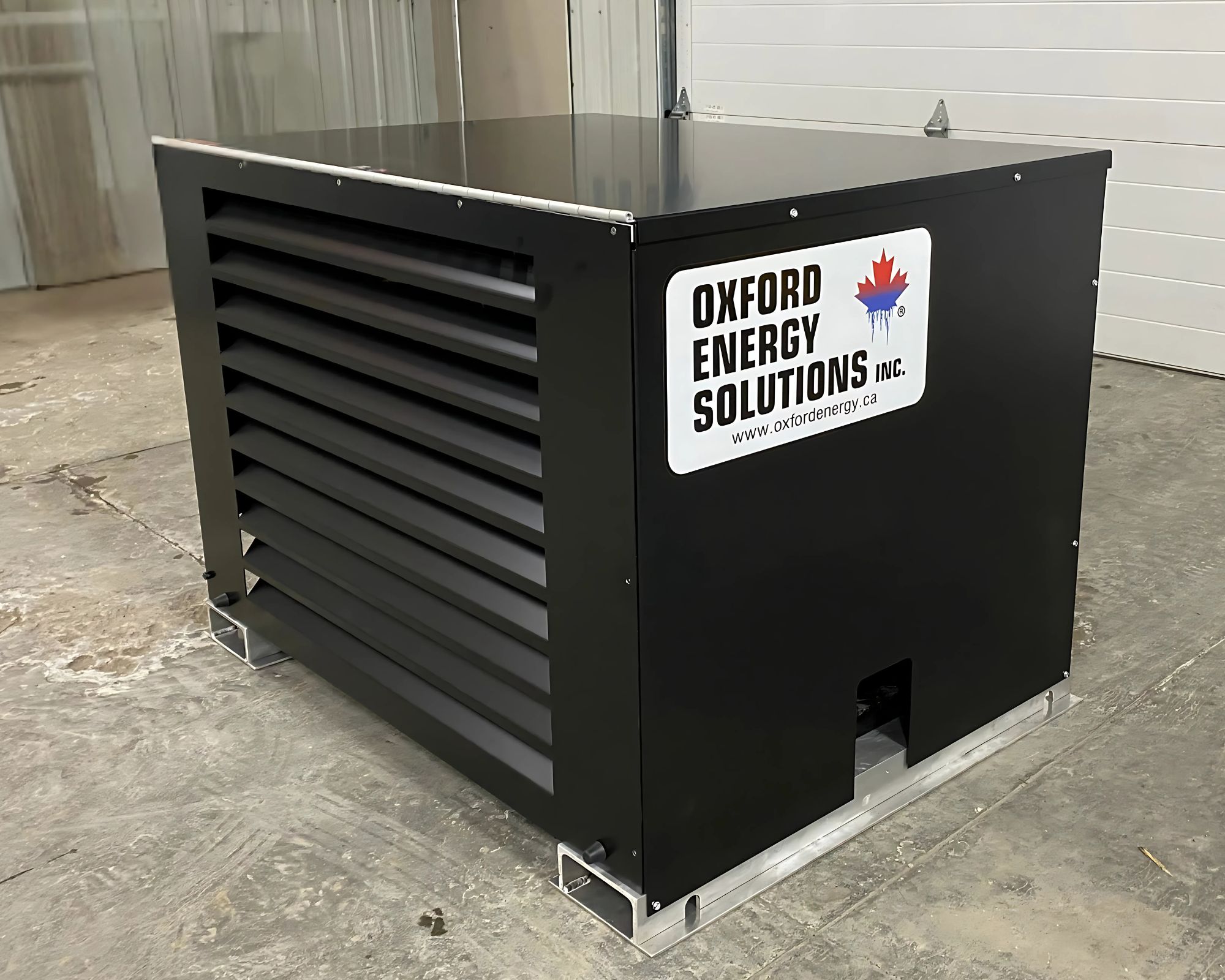

Compact Condensing Unit

- Capacity: 3-5 HP oversized, non-flooding design for reliable performance.

- Versatile Applications: Engineered for low, medium, and high-temp HFC/HFO applications in any ambient condition.

- Energy Efficiency: Floating head technology and low refrigerant charge minimize energy use and environmental impact.

- Superior Construction: Durable powder-coated aluminum enclosure with hinged access panels combines weather resistance with maintenance-friendly design.

- Enhanced Refrigeration: High-performance scroll compressor with HX accumulator for superior liquid subcooling.

- Intelligent Automation: PLC control with EXV management ensures optimal operation in all conditions.

- Seamless Integration: Connects effortlessly to building automation systems for centralized monitoring and energy management.

- User-Friendly Control: Optional 4-inch touchscreen provides easy access to system status, performance data, and settings.

Full-size Condensing Unit: (High-Efficiency FCU-Series)

- Dual-Temp Performance: Non-flooding, variable-capacity system supports low, medium, and high-temp HFC/HFO applications, including two-stage compression.

- High Efficiency: Floating head design, VFD-driven compressors, and low refrigerant charge reduce energy use and increase the refrigeration effect.

- Simplified Architecture: Eliminates low-temp condensers, receivers, and oil separators—cutting mechanical components and refrigerant volume by up to 50%.

- Reliable Cooling: Multi-stage scroll compressors with HX accumulator deliver stable operation, liquid subcooling, and built-in redundancy.

- Smart Control: PLC with EXV management, remote access, and predictive diagnostics ensure precision and uptime.

- Plug & Play Integration: BAS-ready with Ethernet connectivity for fast setup and centralized control.

- Rugged Build: Vinyl-wrapped, corrosion-resistant aluminum cabinet with lockable doors for easy service and all-weather protection.

- Quiet Operation: Engineered to reduce vibration and noise for smooth, efficient performance.

- Flexible Install Options: Rooftop, split, or packaged configurations—pre-wired, pre-programmed, and pre-charged for minimal installation effort.

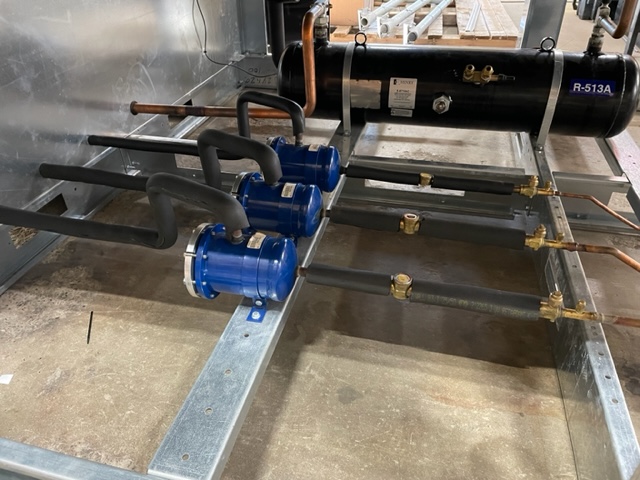

Indoor Rack System

- Flexible Performance: Non-flooding, variable-capacity system supports low, medium, and high-temp HFC/HFO applications in any environment.

- High Efficiency: Floating head technology, VFD-driven multi-stage scroll compressors, and low refrigerant charge reduce energy use and environmental impact.

- Built-In Redundancy: Tandem compressor staging with HX accumulator ensures reliable cooling and consistent liquid subcooling.

- Smart Automation: PLC with EXV management enables precision control, remote access, diagnostics, and predictive maintenance.

- Plug & Play Design: Pre-wired, pre-charged, pre-insulated, and pre-built for fast installation with no downtime.

- Durable & Lightweight: Aluminum structural frame with wrapped panel box; optional HMI screen for local control.

- Customizable Layout: Streamlined piping and configurable sizes to suit various space and load requirements.

- Seamless BAS Integration: Ethernet-enabled connectivity for centralized monitoring and full system control.

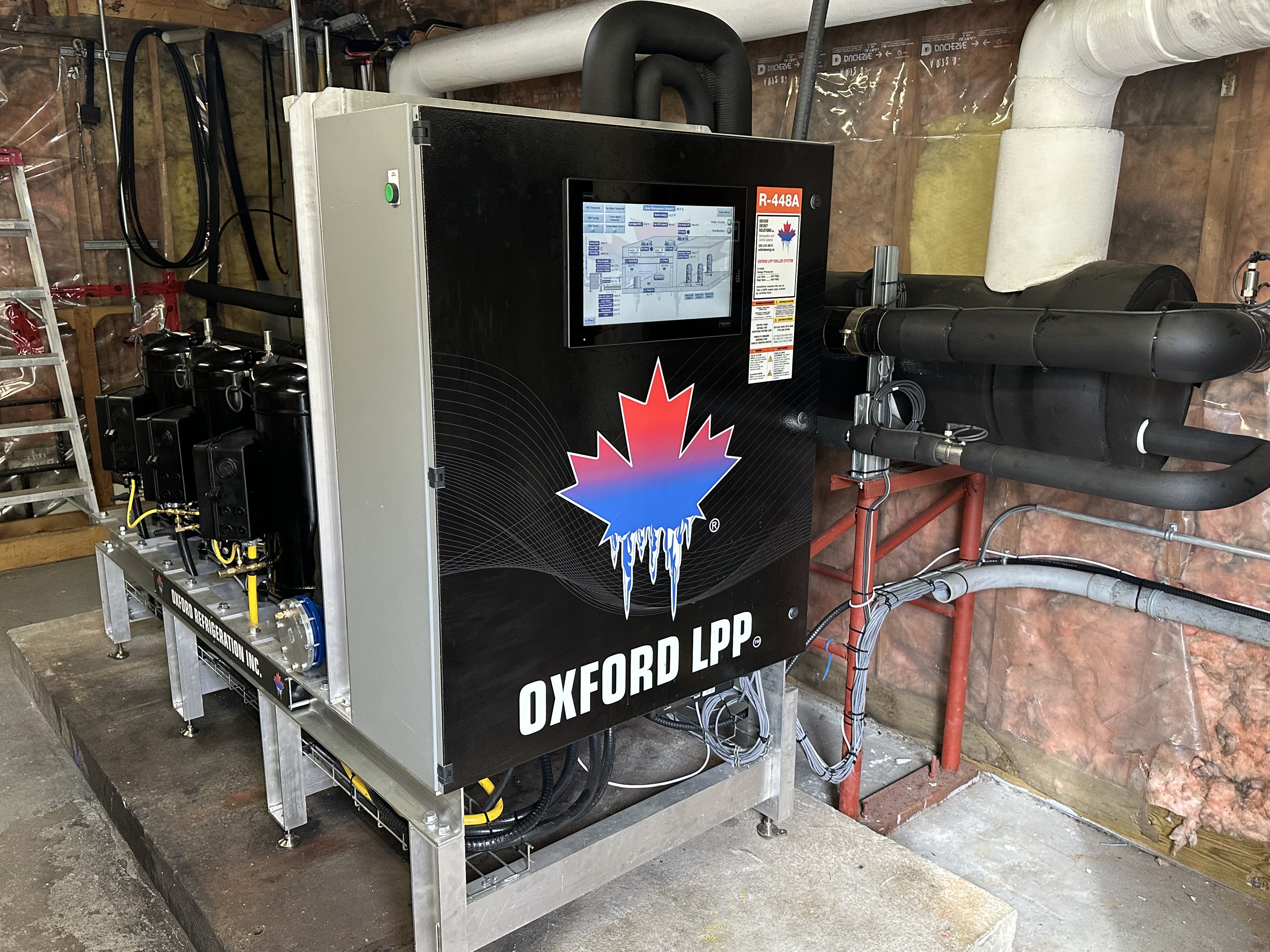

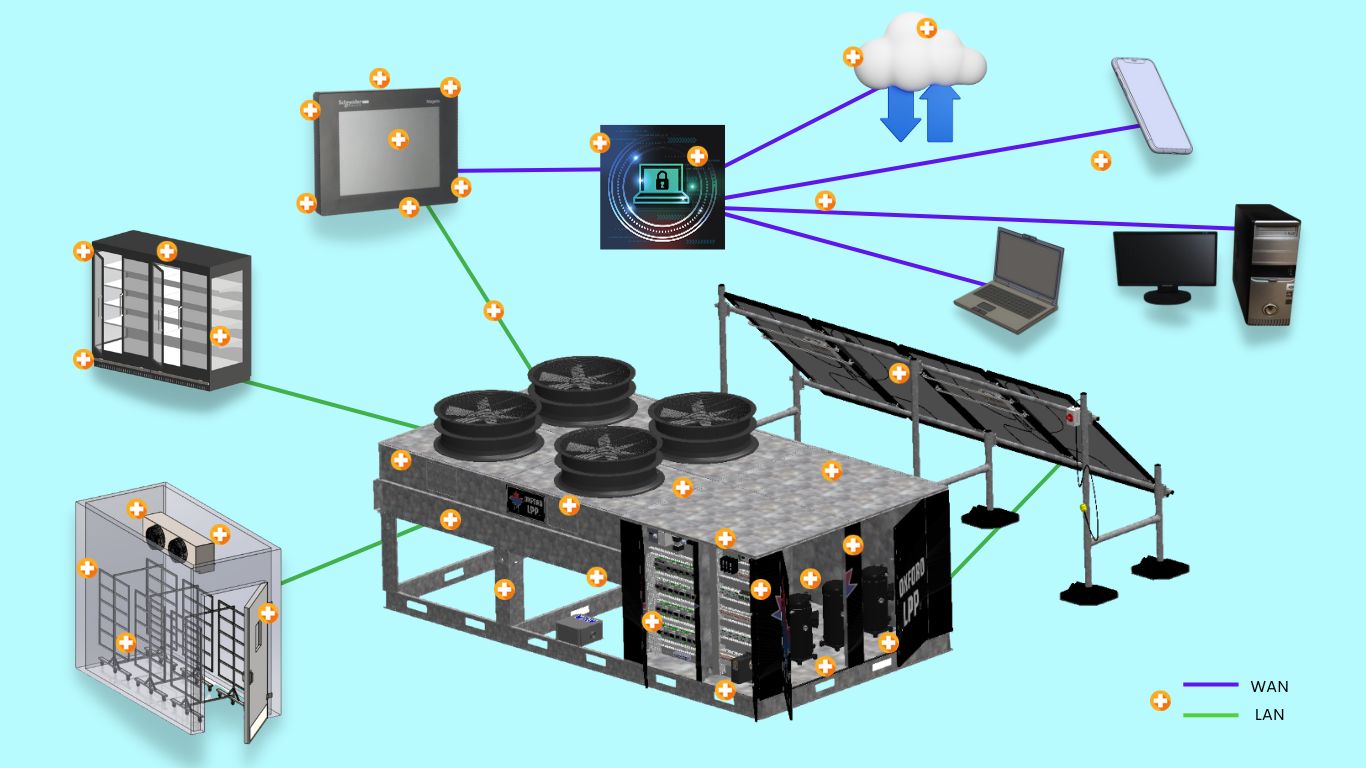

Oxford LPP™ Platform: Smarter Refrigeration by Design

The Oxford LPP™ Platform offers a cutting-edge refrigeration solution that uses a wide range of existing refrigerants, with a primary focus on environmentally friendly HFO refrigerants. Designed for low-pressure systems with high critical temperature characteristics, this technology provides exceptional performance while offering a smooth transition for customers.

Benefits

Aligning with Customer Goals

The Oxford LPP™ Platform is built for adaptability. It integrates seamlessly into existing infrastructure, allowing phased implementation that aligns with your facility's goals and limitations. It allows facilities to adopt HFO low-pressure technology in stages while retaining conventional systems where needed.

Fewer Inputs. Better Performance.

Oxford LPP™ dramatically reduces the system footprint. It minimizes equipment needs by significantly lowering system superheat and heat of compression. It removes the need for a dedicated low-temperature condenser, receiver, and oil separation system, and cuts refrigerant volume by up to 50% compared to traditional designs.

Lowering Cost of Ownership

With fewer components and simplified operation, Oxford LPP™ reduces energy consumption and maintenance requirements—achieving up to 40–60% in total cost savings over conventional rack systems. Installation costs are also reduced, requiring less than half the piping. It supports brazed copper or cost-effective crimped copper/aluminum piping, reducing both material and labor costs without sacrificing reliability.

Next-Level Architecture

Oxford LPP™ features full low-temperature redundancy through a flow-through design. Evaporator temperature changes—whether in low- or medium-temperature applications—require no valve adjustments or architectural changes, greatly simplifying operation. The system also eliminates pressure-compensated or pressure-dependent valves, further reducing complexity.

Engineered for Efficiency

By addressing core inefficiencies in low-temperature compression, Oxford LPP™ minimizes secondary heat loads—including motor and compression heat—by up to 80%. This translates into a more efficient, more responsive refrigeration system.

Built for Compliance

Oxford LPP™ is designed to meet today’s toughest standards, including California regulations and European directives. When paired with compliant evaporator and case layouts, it maintains a low refrigerant charge (under 50 lbs) using environmentally responsible, low-GWP HFO refrigerants.

Patent pending system.